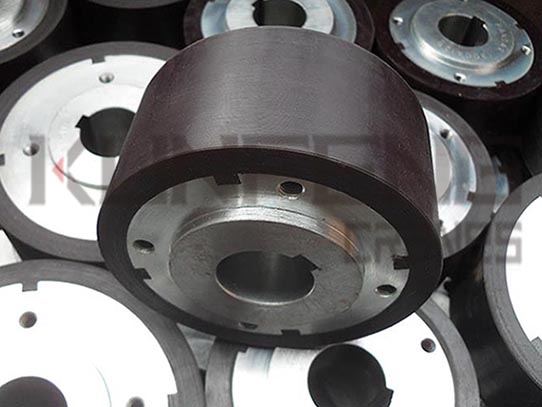

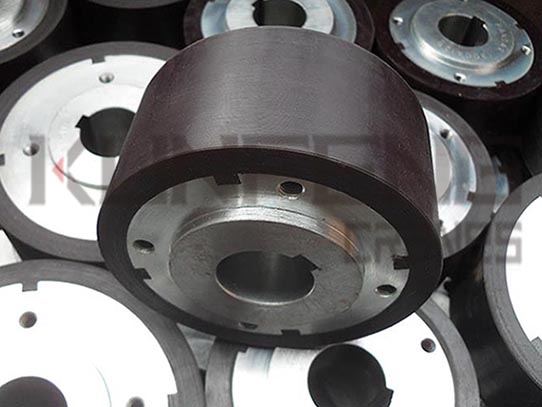

| Elasticity of polyurethane coated wheels origin China

The elasticity and cushioning capacity of polyurethane coated wheel.

CATEGORY:

CREATED:

Oct 28, 2020

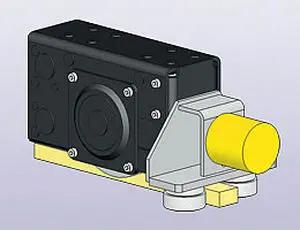

The cushioning and elasticity of polyurethane coated wheels will affect the comfort or smoothness of "riding". This "smooth" feature is achieved by absorbing any bumps, obstacles and roughness on the floor surface through the caster material. The degree of cushioning or rebound depends on the stiffness of the wheel. (That is, how much rubber or polyurethane wheels will deform when driving over bumps or obstacles). For solid wheels, such as polyurethane casters and polyurethane casters, the cushioning/resilience depends on the hardness of the polyurethane or rubber. However, it should also be noted that there are also special types of casters that control cushioning and elasticity in different ways, such as "spring-type" casters or "pneumatic" casters. As described in the "Rolling Resistance Section", rubber casters are usually made at 75-85 on Shore A, while polyurethane casters are usually made at 90-95 on Shore A. The higher the Shore rating, the harder the material. Therefore, the softer the material, the greater the deformation and the higher the absorption capacity over bumps or obstacles, which makes the driving process more stable.

It should be noted that in general, the higher the cushioning, the higher the rolling resistance. Therefore, it is important that both characteristics should be considered at the same time, namely which attribute is most important.

Although both rubber wheels and polyurethane-coated wheels can be made of much softer rubber (at least 30 Shore A), the rubber retains certain key properties at a lower (softer) Shore hardness (such as tear strength) Therefore, polyurethane casters are generally harder than rubber casters. Therefore, rubber casters (usually) provide better cushioning than polyurethane casters.

It should be noted that for many applications, especially indoor applications on smooth floors, there is almost no difference in castor wheel materials. The main benefit is being outdoors.

Can be customized accroding to your needs.

Can be customized accroding to your needs.