| Standard Operating Procedure for Dust Particle Detection in C

Standard Operating Procedure for Dust Particle Detection in Cleanrooms:1. Purpose: To establish the standard operation procedure for detection of dust particles in the clean room (area), and evaluate

CATEGORY:

CREATED:

Apr 06, 2022

Standard Operating Procedure for Dust Particle Detection in Cleanrooms

1. Purpose: To establish the standard operation procedure for detection of dust particles in the clean room (area), and evaluate the air cleanliness.

2. Applicable Scope: The procedure is applicable to detection of dust particles in the clean room(area).

3. Responsibilities: Quality Department head, QA supervisor and QA inspector shall be responsible for implementation of the procedure.

4. Procedures:

4.1 Instrument: Laser dust particle counter (model: CLJ-3106)

4.2 Test state

4.2.1 Before test, the temperature, humidity, and static pressure difference of clean room (area) shall meet the technological requirements.

4.2.2 There are two test states, namely, static state and dynamic state.

4.2.2.1 Static test

Testing can be conducted when the purified air conditioning system of clean room (area) has been in normal operating state, the process equipment has been installed, and there are no production personnel in clean room (area), with the testing personnel indoors not more than two.

4.2.2.2 Dynamic test

Testing can be conducted when the clean room (area) has been in normal production state.

4.3 Test time

Conduct testing after the purified air conditioning system has normally run at least for 30min.

4.4 Dust particle counting

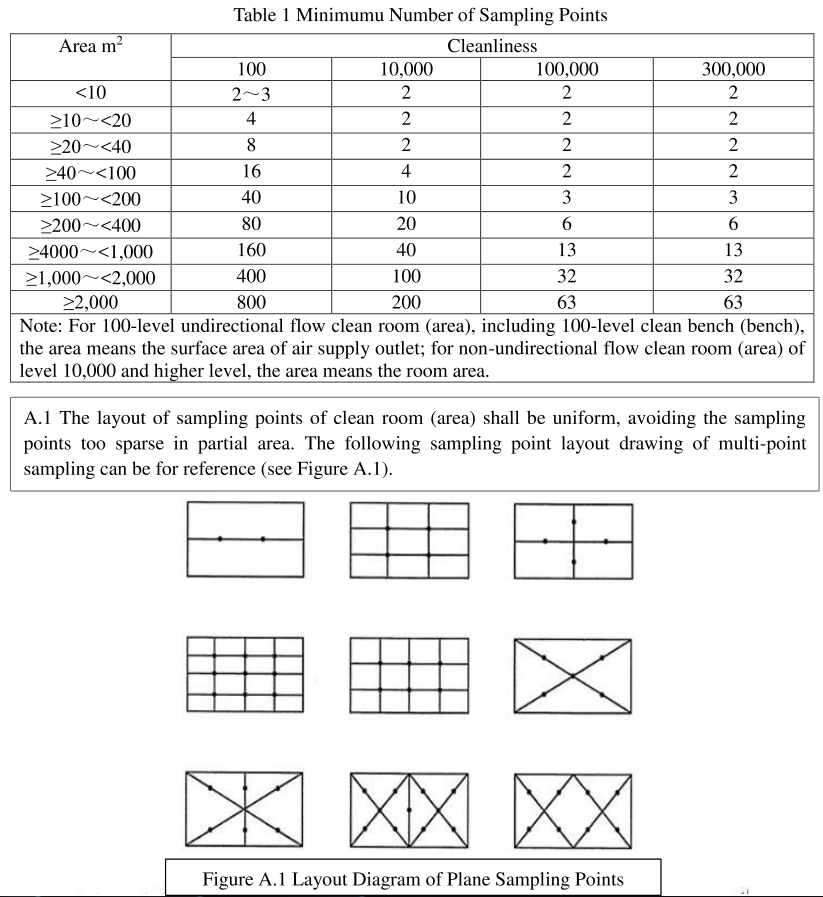

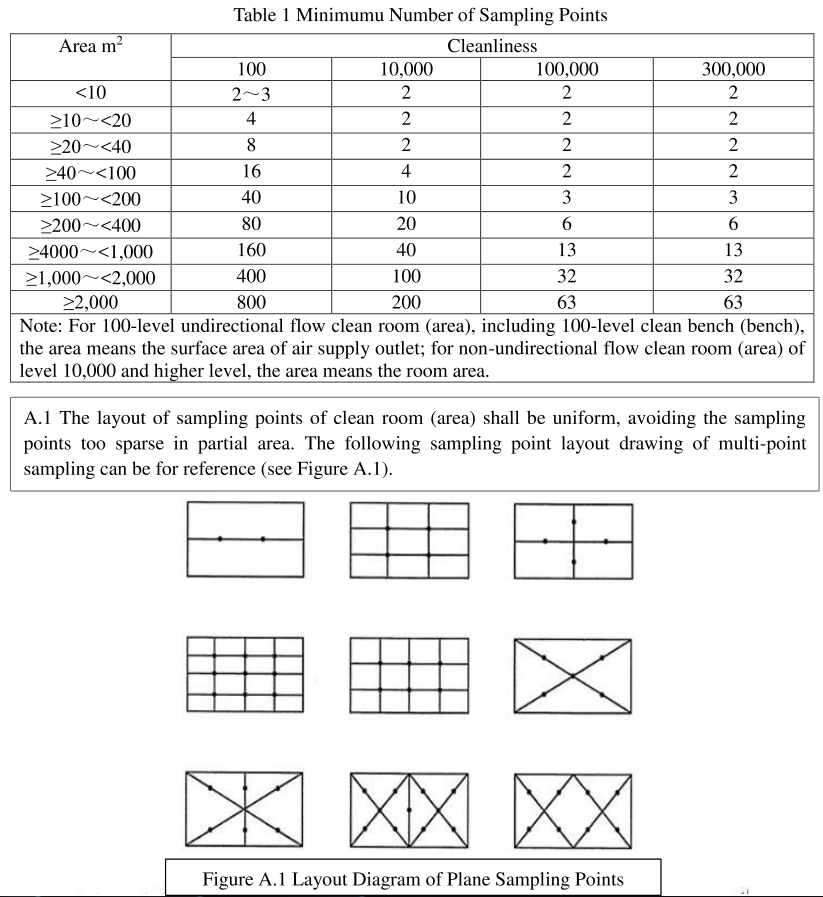

4.4.1 Number of sampling points and their layout

The number of monitoring sampling points of dust particle and their layout can be seen in the attached drawing.

4.4.2 Position of sampling points

The sampling points are usually arranged uniformly on the horizontal plane with a 0.8m height

from the ground.

4.3 Limit for sampling points

The total number of sampling times shall not be more than twice. The sampling number of times for each sampling point can be more than once, and the sampling number of times for different sampling points may be different.

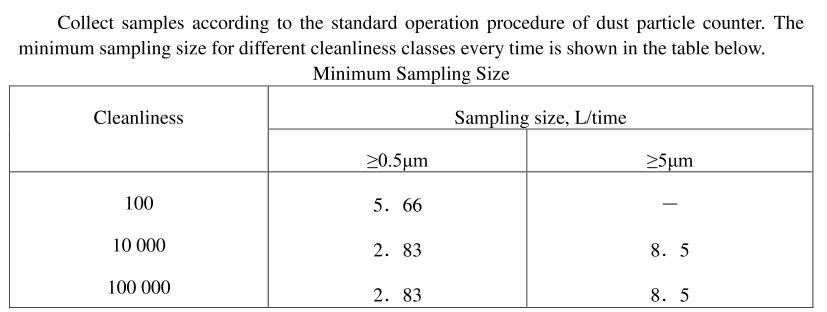

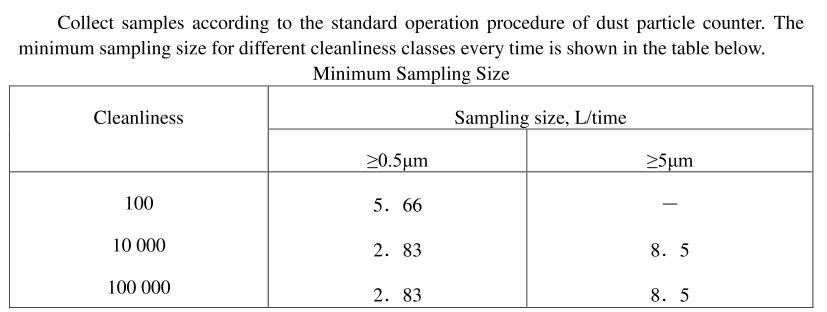

4.4.4 Sampling

4.5 Precautions for sampling

4.5.1 Sampling can be performed only when it is confirmed that the air supply volume and

differential pressure of clean room (area) reach the requirements.

4.5.2 For unidirectional flow, the sampling pipe orifice of counter shall directly face the airflow direction, and for non- directional flow, the sampling pipe orifice shall be upward.

4.5.3 The testing personnel shall be on the downwind side of sampling port during the sampling.

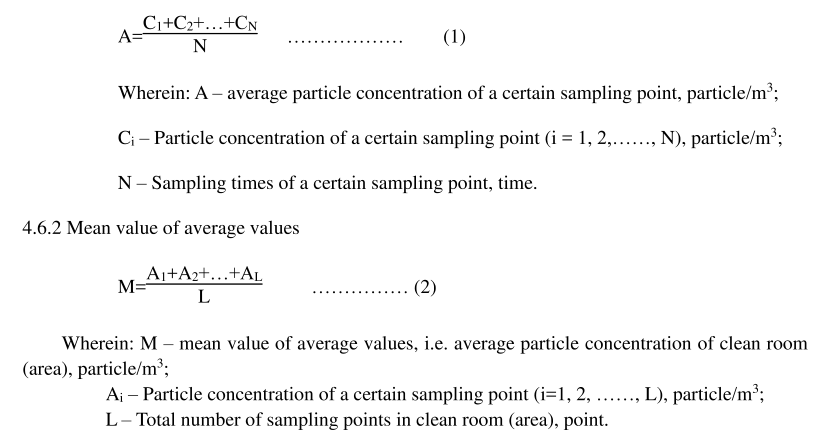

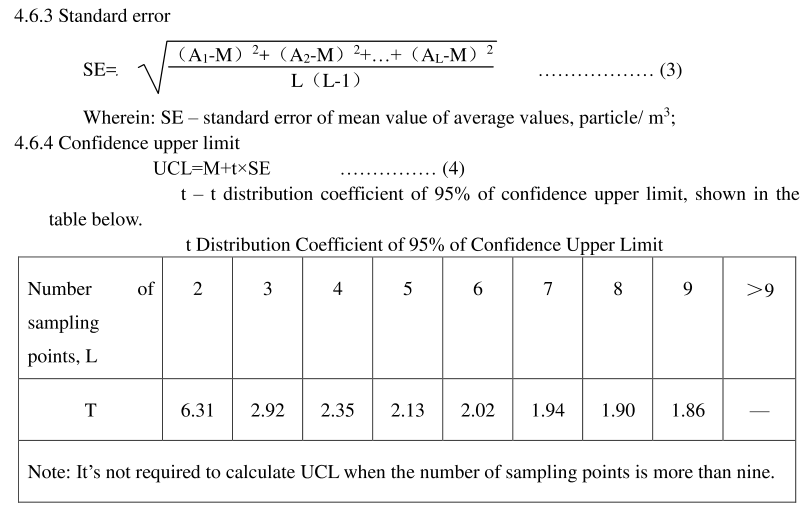

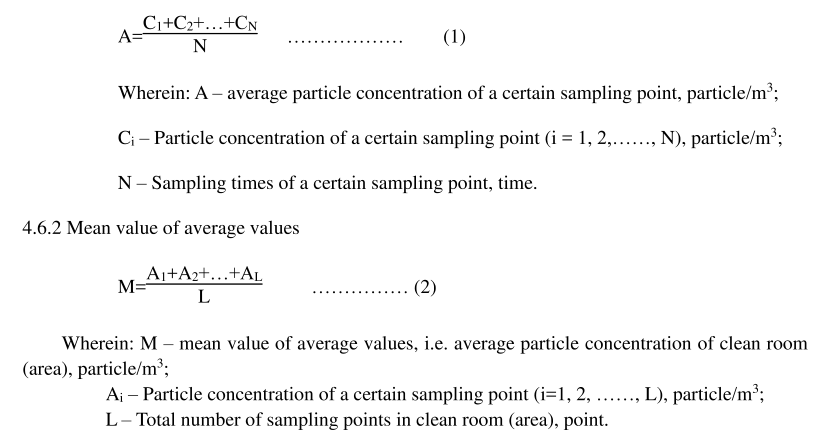

4.6 Calculation of results

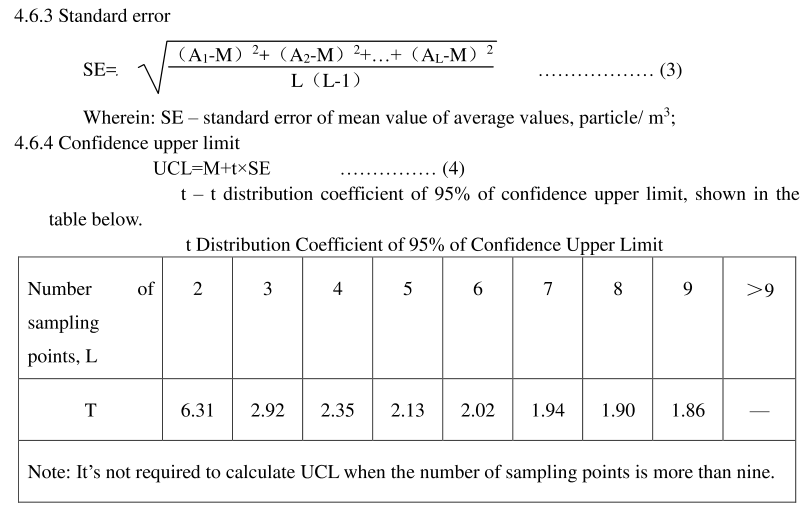

The sample data of airborne particle concentration shall be calculated according to the following steps:

4.6. 1 Average particle concentration of sampling point

4.7 Evaluation of results

4.7.1 The average particle concentration of each sampling point must be lower than or equal to the

specified level limit, namely, A:≤level limit.

4.7.2 95% of confidence upper limit of the mean value of average values of particle concentration of all sampling points must be lower than or equal to the specified level limit, namely, UCL≤level limit.

4.8 Records

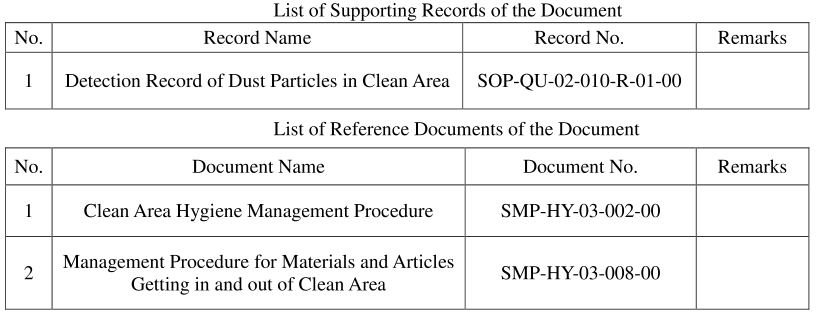

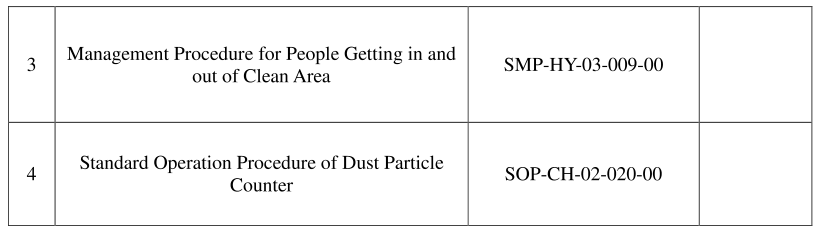

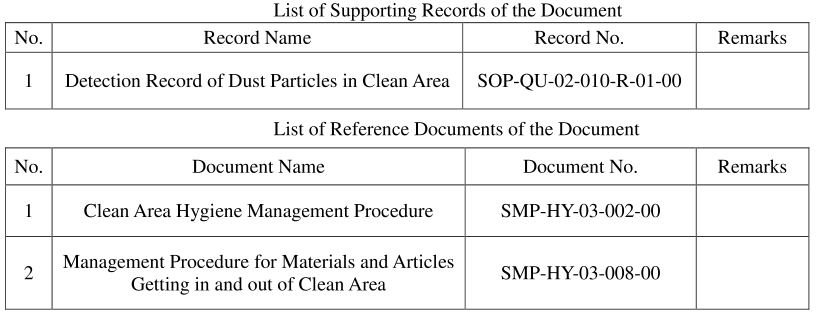

5. Keeping and Management of Relevant Records:“Detection Record of Dust Particles in Clean Area”shall be preserved in Quality Department, and managed by QA inspector.

6. Supplementary Provisions:

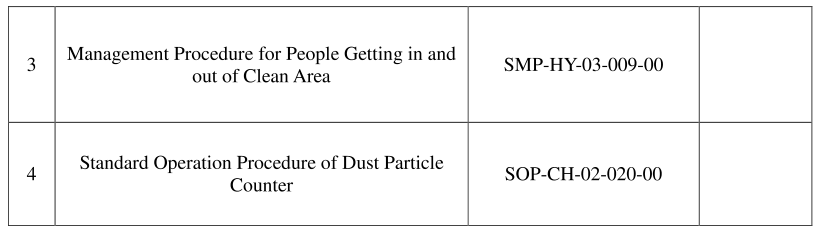

7. The document is drafted by QA lab, reviewed by QA supervisor, and approved by Quality Department head.