| 2t Accurate Positioning Crane Hoist for High Technology Industry

KUNFENG CRANES has a wide range of product, including EOT cranes and electric hoist, e.g. overhead crane with automatic positioning system, rail mounted gantry crane, clean room cranes for new energy industry, electric belt hoist for photovoltaic workshop, compact wire rope hoist for no more than 132 tons lifting. In addition, wheel block system and polyurethane wheels are welcomed in logistic industry and stackers.

For most high technology industry, high accuracy positioning is a great feature for the production.

In semiconductor industry, a clean room cranes greatly help production. Following are some benefits of clean room cranes:

• Contamination control: Clean room cranes are built with features to minimize particulate generation and contamination, ensuring a clean and controlled production environment.

• Precision handling: The high accuracy positioning of clean room cranes allows for the safe and precise handling of fragile and expensive semiconductor equipment, reducing the risk of damage or errors.

• Optimized workflow: Clean room cranes help streamline the production process by facilitating efficient movement and positioning of equipment, contributing to increased productivity and reduced downtime.

What are the factors affect accuracy of cranes?

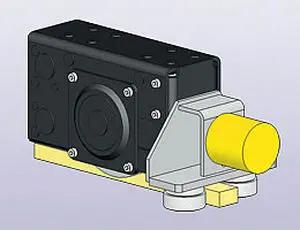

• Quality components: Using high-quality components, such as precision gears, sensors, and control systems, is essential. These components should be designed to provide accurate measurements and precise control over the crane's movements.

• Advanced control systems: Implementing advanced control systems, such as servo motor drives or frequency inverters, allows for precise control of the crane's movements. As an OEM crane factory, SEW, Schneider, Siemens, ABB components all available for your customized crane. These electrical systems can provide accurate positioning, speed control, and load management, minimizing errors and optimizing performance.

• Regular maintenance and inspection: Performing regular maintenance and inspections help identify and address any issues that may affect accuracy. This includes checking for wear, lubricating components, and ensuring proper alignment and calibration. Our experienced technists will help your every lifting need.

Fixed-point positioning refers to the use of various technical means to determine the precise location of an object or individual in space. This positioning technology is widely used in many fields, including navigation and map services, driverless driving, logistics, environmental monitoring, etc.

We focus on the advanced heavy loads lifting solution, supplying all kinds of time saving products, no matter it's up to 40 tons wheel block system, anti-sway electric wire rope hoist.

If you would like to get more information about our company and our capabilities, we would welcome your inquiry. For additional information, contact KUNFENG Crane today.