| Pharmaceutical Cleanroom Crane Manufacturing Process

For pharmaceutical industry, cleanroom cranes are designed to operate in controlled environments, minimizing the risk of contamination and meeting strict cleanliness standards. They play a crucial role in maintaining the quality and safety of pharmaceutical products throughout the manufacturing process.

What are the process of a crane manufacturing, Let's find out together!

Step 1: Design

The very first step in the process of building a cleanroom crane is designing. This process is done by expert engineers who generate blueprints and specifications, based on the required demand and capacity of the crane. During the designing process, engineers consider factors like the height of the crane, the weight capacity, and other engineering parameters.

Compared with the traditional crane with a stainless steel cover, belt cranes are more features compact structure and less abrasion flakes in pharmaceutical industry.

Step 2: Material Processing and Production

After the blueprints are approved, the manufacturer proceeds to process the metal and other materials necessary for constructing the crane. Heavy-duty steel is usually the primary material utilized, and it must be prepared before it can be employed in the construction of the crane. This preparation process includes cutting, shaping, and drilling, all carried out in accordance with the precise specifications outlined in the design.

Step 3: Welding and Fabrication

After the metal has been prepped, it's time for welding and fabrication. With the help of robotic and manual welding, workers can accurately fabricate and weld the crane's structure, bringing it to life as per the provided blueprints and specifications.

For cleanroom cranes, a smooth and non-shedding surface is the most important thing. Our QC team plays a vital role in maintaining high standards and meeting customer expectations. They conducts a thorough inspection of the surfaces and imperfections, including the dents, scratches, uneven coverage, runs, drips, etc.

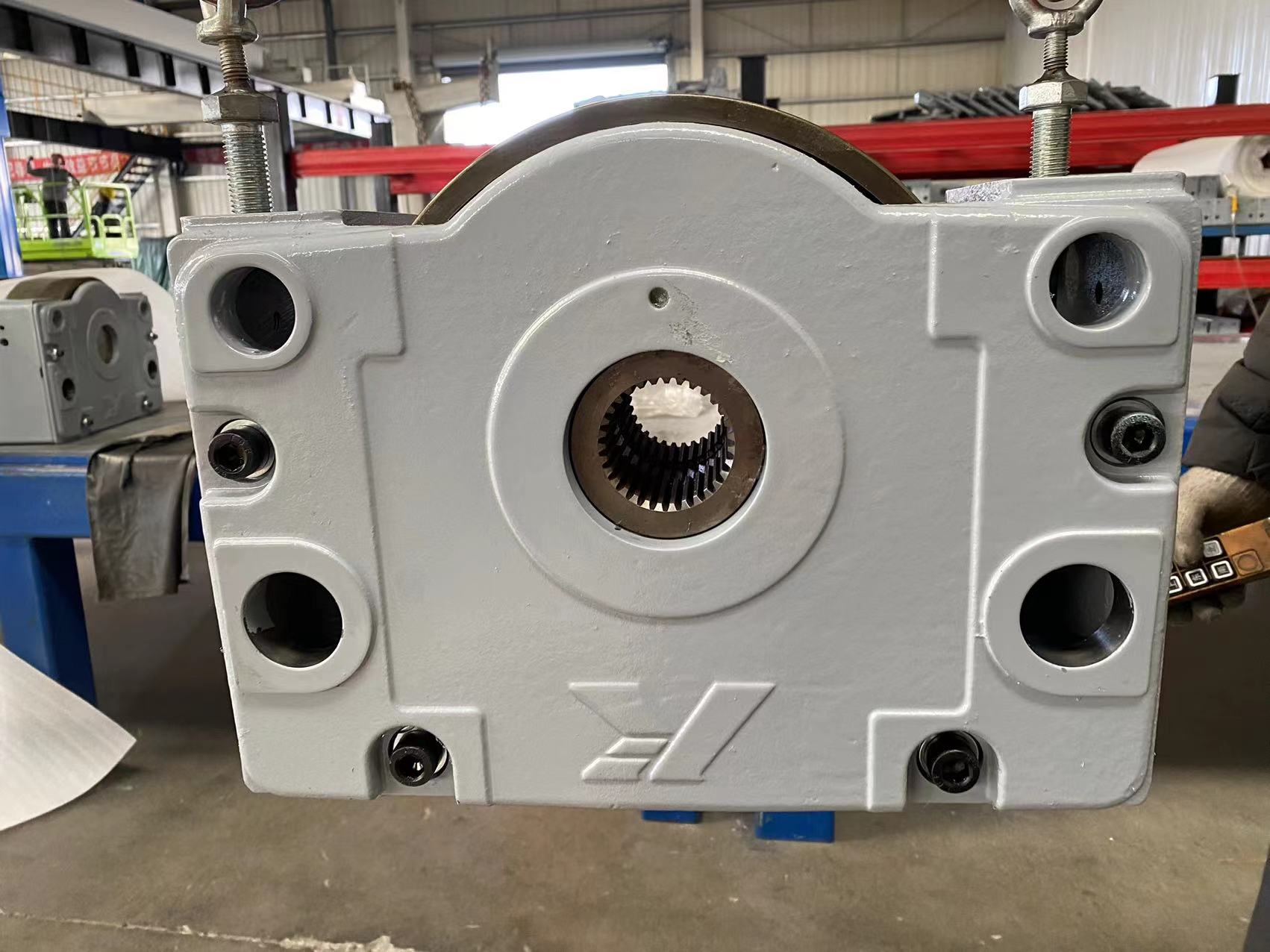

Step 4: Assembly and Testing

After the completion of the structural assembly, the crane undergoes a series of tests to ensure its safety. These tests check the integrity of the entire structure and make sure that all components are functioning properly. If the crane passes the inspection and testing phases, it is then disassembled and transported to the customer's site.

Step 5: Delivery and Reassembly

After disassembly, the crane is transported to the construction site in parts and reassembled, which can take several days.

Additional options for cleanness certificates, factory inspections, and specific accessories are available. For further questions, please contact us via online message or email at sale@kfqizhongji.com