| Tandem Belt Hoist for Cleanrooms and Controlled Environment

Tandem hoist crane refers to the operation of two hoists working in synchronization to lift and move a heavy load. In this configuration, two hoists are attached to a single load, each hoist sharing the load weight. Tandem hoisting is commonly used when the weight of the load exceeds the capacity of a single hoist, or when a more balanced and controlled lifting operation is required.

Benefits of Tandem Hoist:

1. Increased Lifting Capacity: By utilizing two belt hoists, tandem hoisting allows for lifting capacities beyond the capabilities of a single hoist. This is particularly useful in industries such as construction, shipbuilding, or heavy machinery manufacturing, where extremely heavy loads need to be lifted and moved.

2. Improved Load Control: Tandem hoisting provides better load control and balance for overhead crane in cleanrooms. By distributing the load weight between two hoists, the load can be lifted and moved more evenly, reducing the risk of load imbalance, swinging, or tilting. This ensures safer and more stable lifting operations, minimizing the potential for accidents or damage to the load or equipment.

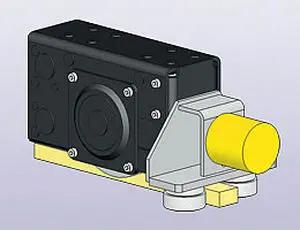

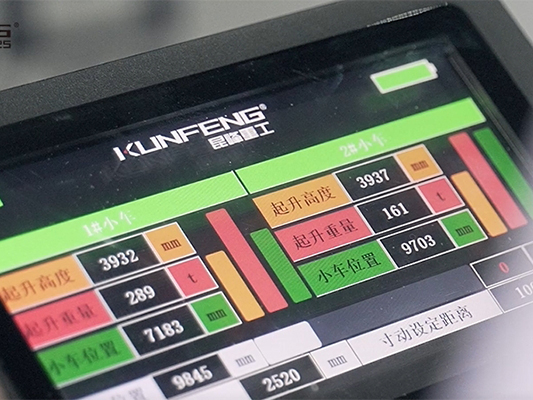

3. Enhanced Precision and Maneuverability: The use of belt hoist allows for more precise positioning and maneuverability of the load. Our belt hoist has a excellent positioning feature, within 1mm microspeed moving and hoisting. The synchronized operation of the two hoists enables fine adjustments and precise control, especially when working in tight spaces or when accurate load placement is critical.

4. Redundancy and Safety: Tandem hoisting provides a level of redundancy in case one hoist fails or malfunctions. If one hoist experiences an issue, the other hoist can continue to support and control the load, ensuring safety and preventing potential accidents or delays.

Applications of Tandem Hoist:

Tandem hoisting is commonly employed in various industries and applications, including:

- Construction: Lifting heavy construction materials such as steel beams, precast concrete elements, or large machinery components.

- Shipbuilding: Maneuvering and installing ship sections, heavy ship components, or shipyard infrastructure.

- Heavy Machinery Manufacturing: Lifting and positioning heavy machinery parts during assembly or maintenance operations.

- Power Generation: Handling large turbine components, generators, or heavy equipment in power plants.

- Oil and Gas: Lifting and moving heavy equipment, pipes, or offshore structures during installation or maintenance.

While for belt hoist, its cleanness design and corrosion resistant advantages make the overhead crane a good choice for controlled environment. Especially for micro-electronics production and handling in semiconductor industry and electronic industry, safe and clean handling in food industry and pharmaceutical industry and so on. Check this article for more features of cleanroom belt hoist.

In summary, tandem belt hoist is an effective solution for lifting and moving heavy loads beyond the capacity of a single hoist. Its benefits include increased lifting capacity, improved load control, enhanced precision, and added safety. The application of tandem hoist is widespread across industries that require the handling of large and heavy objects.

Contact KUNFENG CRANES today to get a tailored solution.