| Types of Gantry Cranes with Capacity of 5t/10t/50t/80t/100t

Gantry cranes are an essential piece of equipment in various industries, including construction, logistics, manufacturing, and others. They are used for lifting and moving heavy loads and materials within a confined area. Gantry cranes are characterized by their ability to move along a rail or track system, which is supported by a framework or structure. There are different types of gantry cranes, each with unique features and applications. In this article, we will discuss the types of gantry cranes and their specific uses.

1. Full gantry crane

The full gantry crane is the most common type of gantry crane and is used in a wide range of industries. It is characterized by a bridge that spans the entire width of the gantry, supported by two or more legs. The crane moves along a rail system, which is attached to the legs. Full gantry cranes come in different sizes and lifting capacities, depending on the application. Capacity range from 2 ton to 100 ton, and the span and lifting height can be customized.

The full gantry crane is the most common type of gantry crane and is used in a wide range of industries. It is characterized by a bridge that spans the entire width of the gantry, supported by two or more legs. The crane moves along a rail system, which is attached to the legs. Full gantry cranes come in different sizes and lifting capacities, depending on the application. Capacity range from 2 ton to 100 ton, and the span and lifting height can be customized.

• Full gantry cranes are commonly used in construction sites, shipyards, and manufacturing plants for lifting and moving heavy loads. They are also used in logistics and warehousing for loading and unloading containers and pallets from trucks and ships.

2. Semi-gantry crane

The semi-gantry crane is similar to the full gantry crane, but with one end supported by a structure, such as a building or wall, and the other end supported by a leg or trolley system. The crane moves along a rail system, which is attached to the leg or trolley. Semi-gantry cranes are used for applications where one end of the crane needs to be supported by an existing structure.

• Semi-gantry cranes are commonly used in manufacturing plants and workshops for lifting and moving heavy machinery and equipment. They are also used in construction sites for lifting and moving construction materials.

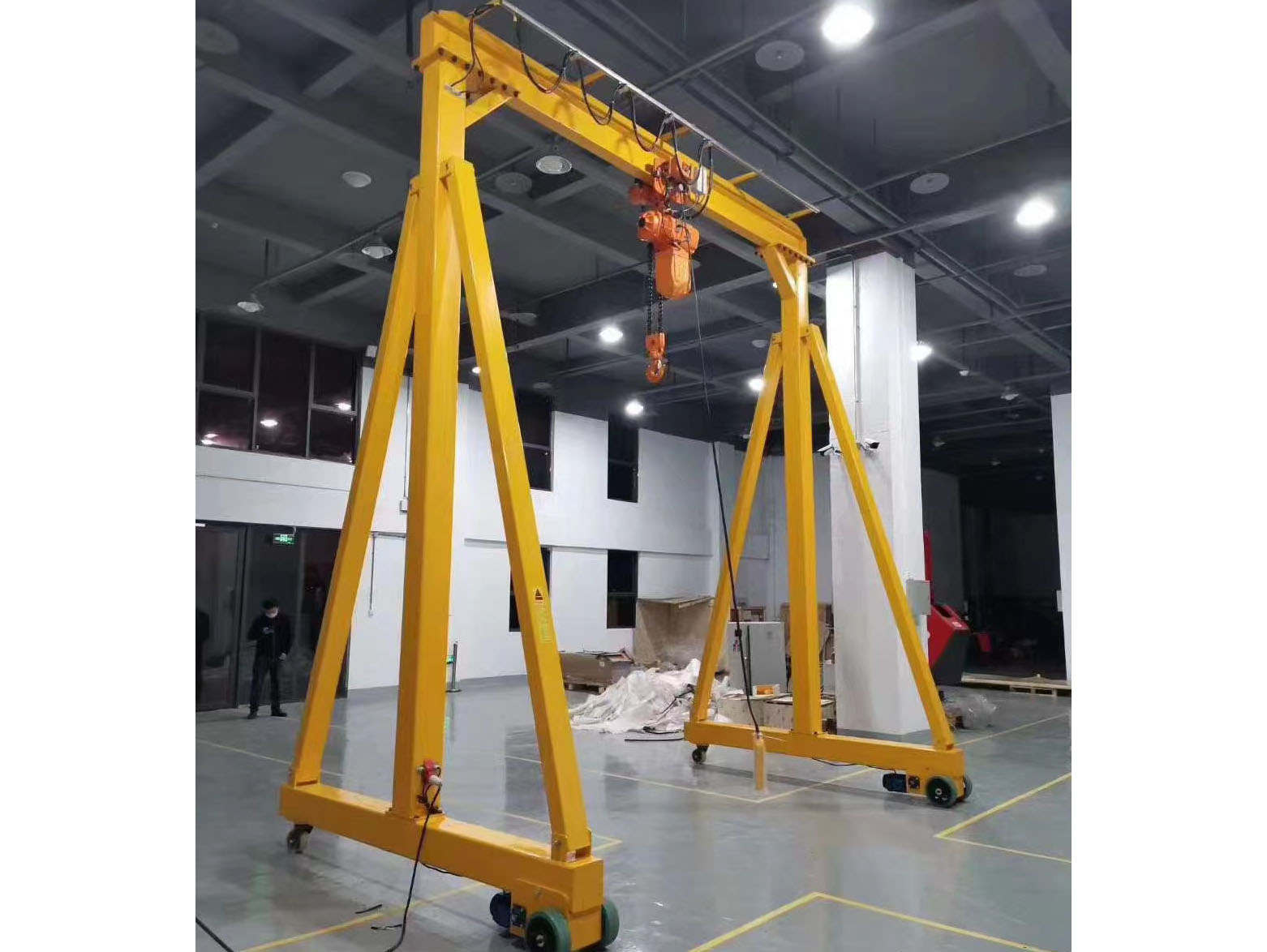

3. Portable gantry crane

The portable gantry crane is a lightweight and compact gantry crane that can be easily assembled and disassembled. Portable cranes are sometimes also referred to as A-frame hoists, rolling cranes, or gantries because of the triangular (“A”) shape of their legs. Meanwhile, there are four swivel casters to help move into place when preparing to hoist or move heavy objects. Portable gantry cranes are designed for applications where a temporary lifting solution is required.

The portable gantry crane is a lightweight and compact gantry crane that can be easily assembled and disassembled. Portable cranes are sometimes also referred to as A-frame hoists, rolling cranes, or gantries because of the triangular (“A”) shape of their legs. Meanwhile, there are four swivel casters to help move into place when preparing to hoist or move heavy objects. Portable gantry cranes are designed for applications where a temporary lifting solution is required.

• Portable gantry cranes are commonly used in workshops and small manufacturing plants for lifting and moving small loads and materials.

In conclusion, gantry cranes are essential equipment in various industries, and choosing the right type of gantry crane depends on the specific application. Full gantry cranes are the most common type and are used in a wide range of industries. Semi-gantry cranes are used for applications where one end of the crane needs to be supported by an existing structure. Portable gantry cranes are designed for temporary lifting solutions. Contact KUNFENG CRANES to get more professional assistant for your business.