| About the maintenance of polyurethane rubber rollers origin China

The maintenance of polyurethane rubber rollers.

CATEGORY:

CREATED:

Oct 26, 2020

In the process of use, the polyurethane rubber roller will be affected by external factors and cause problems such as peeling, broken copper, abrasion, etc. At this time, we must first see whether the degree of damage is serious. If it is a large area of damage, it should be sent to the manufacturer immediately. Repair or replacement, otherwise, you can follow the instructions or professional guidance for repair work.

Precautions for maintenance of polyurethane rubber rollers:

1. To repair the rubber roller, pour the rubber repair agent curing agent into the iron box, stir it evenly (1:1), and then pour it to the damaged area of the rubber roller.

2. Surface treatment: roughen the polyurethane rubber roller to be repaired, clean, decontaminate, degrease, and dry.

3. If there is no effective repair material to strengthen it, the rubber roller works under the condition of local tension inconsistency, which is very easy to cause the expansion of damage.

Of course, the above is for when the damage degree is light. It is not appropriate to replace the polyurethane rubber roller when the damage degree is light. You must know that the cost of the polyurethane rubber roller is relatively high, and the replacement time is likely to affect the production. Progress, so doing the repair yourself can reduce a lot of costs.

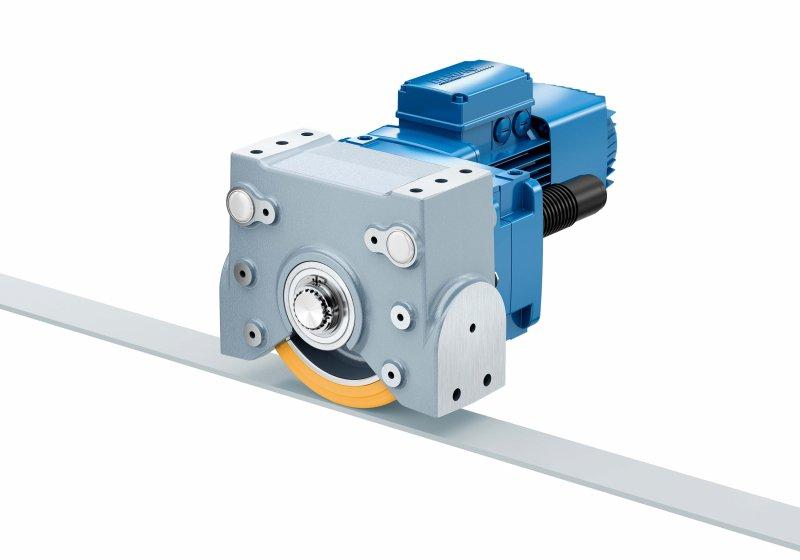

If the polyurethane rubber roller is too strong, the polyurethane friction wheel will still be broken, and there may be cuts. The biggest difference with rubber is that the polyurethane friction wheel cuts usually do not spread, and the polyurethane friction wheel is likely to become lumpy over time. Compared with rubber, the polyurethane friction wheel has a longer service life.

Can be cutomized accrodng to your needs.

Precautions for maintenance of polyurethane rubber rollers:

1. To repair the rubber roller, pour the rubber repair agent curing agent into the iron box, stir it evenly (1:1), and then pour it to the damaged area of the rubber roller.

2. Surface treatment: roughen the polyurethane rubber roller to be repaired, clean, decontaminate, degrease, and dry.

3. If there is no effective repair material to strengthen it, the rubber roller works under the condition of local tension inconsistency, which is very easy to cause the expansion of damage.

Of course, the above is for when the damage degree is light. It is not appropriate to replace the polyurethane rubber roller when the damage degree is light. You must know that the cost of the polyurethane rubber roller is relatively high, and the replacement time is likely to affect the production. Progress, so doing the repair yourself can reduce a lot of costs.

If the polyurethane rubber roller is too strong, the polyurethane friction wheel will still be broken, and there may be cuts. The biggest difference with rubber is that the polyurethane friction wheel cuts usually do not spread, and the polyurethane friction wheel is likely to become lumpy over time. Compared with rubber, the polyurethane friction wheel has a longer service life.

Can be cutomized accrodng to your needs.