| Talking about the application of rubber wheels for polyurethane products

Talking about the application of rubber wheels for polyurethane products.

CATEGORY:

CREATED:

Dec 10, 2020

Polyurethane rubber wheel elastomer is a non-metallic material that best meets the requirements of mines and can replace some metal materials. Polyurethane elastomer products used in mines include sieve plates, elastomer linings, and conveyor belts. Polyurethane rubber sieve plates include loose sieve plates, tension sieve plates, and slotted sieve plates. Polyurethane rubber screen has excellent wear resistance, water resistance, oil resistance, vibration absorption and noise reduction, high strength, and strong adhesion to the metal frame. It has low noise, good self-cleaning effect, and reduces the load of the screen machine, saves energy consumption, and extends The life of the screen, the high quality of the polyurethane rubber wheel screening.

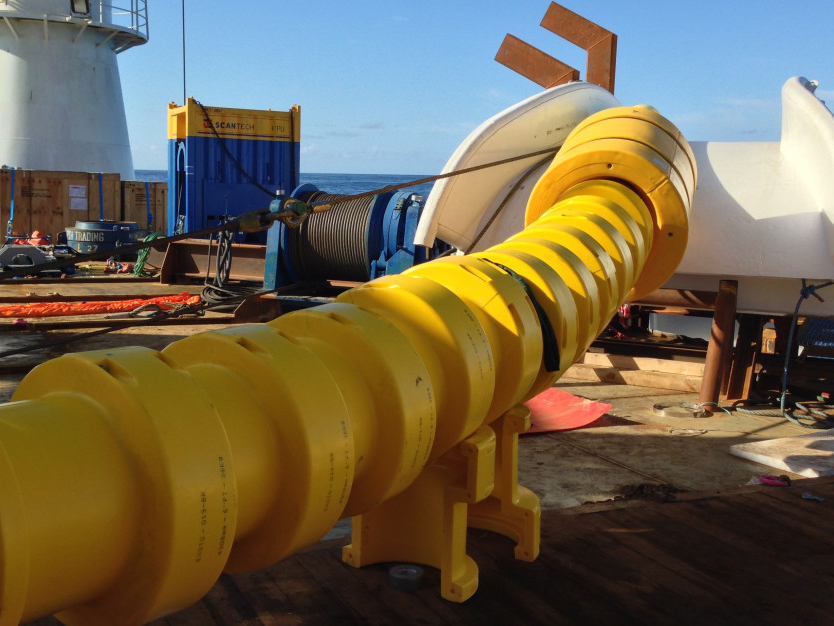

Casting polyurethane rollers, roller frame rollers, and rubber rollers are polyurethane rubber rollers and rubber rollers made of liquid polyurethane rubber by casting. Compared with ordinary rollers and rubber rollers, it has higher mechanical strength (2-3 times of natural rubber), excellent wear resistance (5-10 times of natural rubber), outstanding compression resistance; hardness range Wide, and still has high elasticity under high hardness (this is a characteristic that other rubber types do not have); high surface finish; superior mechanical processing performance; and metal adhesion is much higher than ordinary rubber, which is more suitable for a certain line speed And use under high pressure. Recently, polyurethane rollers and rubber rollers have developed rapidly, and a large number of ordinary rubber rollers used previously have been replaced by new polyurethane rubber rollers.

Many mining equipment, such as shakers, flotation machines, special concentrators, streamers, spiral flow troughs, shredders, magnetic separators, pipes and elbows, contact materials such as gravel and require wear-resistant linings; mining monorails The steel core polyurethane driving wheel of the crane, the flame-retardant and antistatic polyurethane conveyor belt, the TPU sheath of the equipment cable, the dust ring, the shock-absorbing block, etc., polyurethane elastomer is the preferred material.

Casting polyurethane rollers, roller frame rollers, and rubber rollers are polyurethane rubber rollers and rubber rollers made of liquid polyurethane rubber by casting. Compared with ordinary rollers and rubber rollers, it has higher mechanical strength (2-3 times of natural rubber), excellent wear resistance (5-10 times of natural rubber), outstanding compression resistance; hardness range Wide, and still has high elasticity under high hardness (this is a characteristic that other rubber types do not have); high surface finish; superior mechanical processing performance; and metal adhesion is much higher than ordinary rubber, which is more suitable for a certain line speed And use under high pressure. Recently, polyurethane rollers and rubber rollers have developed rapidly, and a large number of ordinary rubber rollers used previously have been replaced by new polyurethane rubber rollers.

Many mining equipment, such as shakers, flotation machines, special concentrators, streamers, spiral flow troughs, shredders, magnetic separators, pipes and elbows, contact materials such as gravel and require wear-resistant linings; mining monorails The steel core polyurethane driving wheel of the crane, the flame-retardant and antistatic polyurethane conveyor belt, the TPU sheath of the equipment cable, the dust ring, the shock-absorbing block, etc., polyurethane elastomer is the preferred material.