| Safety Device of Crane & Electric Hoist - Professional China Crane Manufacturer

Crane safety is of utmost importance in any industrial setting to prevent accidents and ensure the well-being of workers. To achieve this, cranes should be equipped with various safety devices that help to mitigate risks and enhance overall operational safety. Here are six essential safety devices commonly found on cranes:

1. Overload Protection System: This system prevents the crane from lifting loads beyond its rated capacity. It typically consists of load sensors or load cells that measure the weight being lifted. If the load exceeds the predetermined limit, an alarm will sound, and the crane's operation will be automatically halted.

2. Limit Switches: Limit switches are used to control the movement of the crane by setting upper and lower limits for specific motions. These switches can be programmed to stop the crane from moving beyond these predetermined positions, preventing collisions, overruns, or other hazardous situations. Mainly includes:

2. Limit Switches: Limit switches are used to control the movement of the crane by setting upper and lower limits for specific motions. These switches can be programmed to stop the crane from moving beyond these predetermined positions, preventing collisions, overruns, or other hazardous situations. Mainly includes:

• Upper limits and lower limits

• Travel Limiters: Travel limiters set boundaries for the crane's movement, preventing it from traveling outside the designated area. These limiters can be programmed to restrict travel in specific directions, ensuring that the crane operates within safe working zones.They are mainly equipped with electrc hoists.

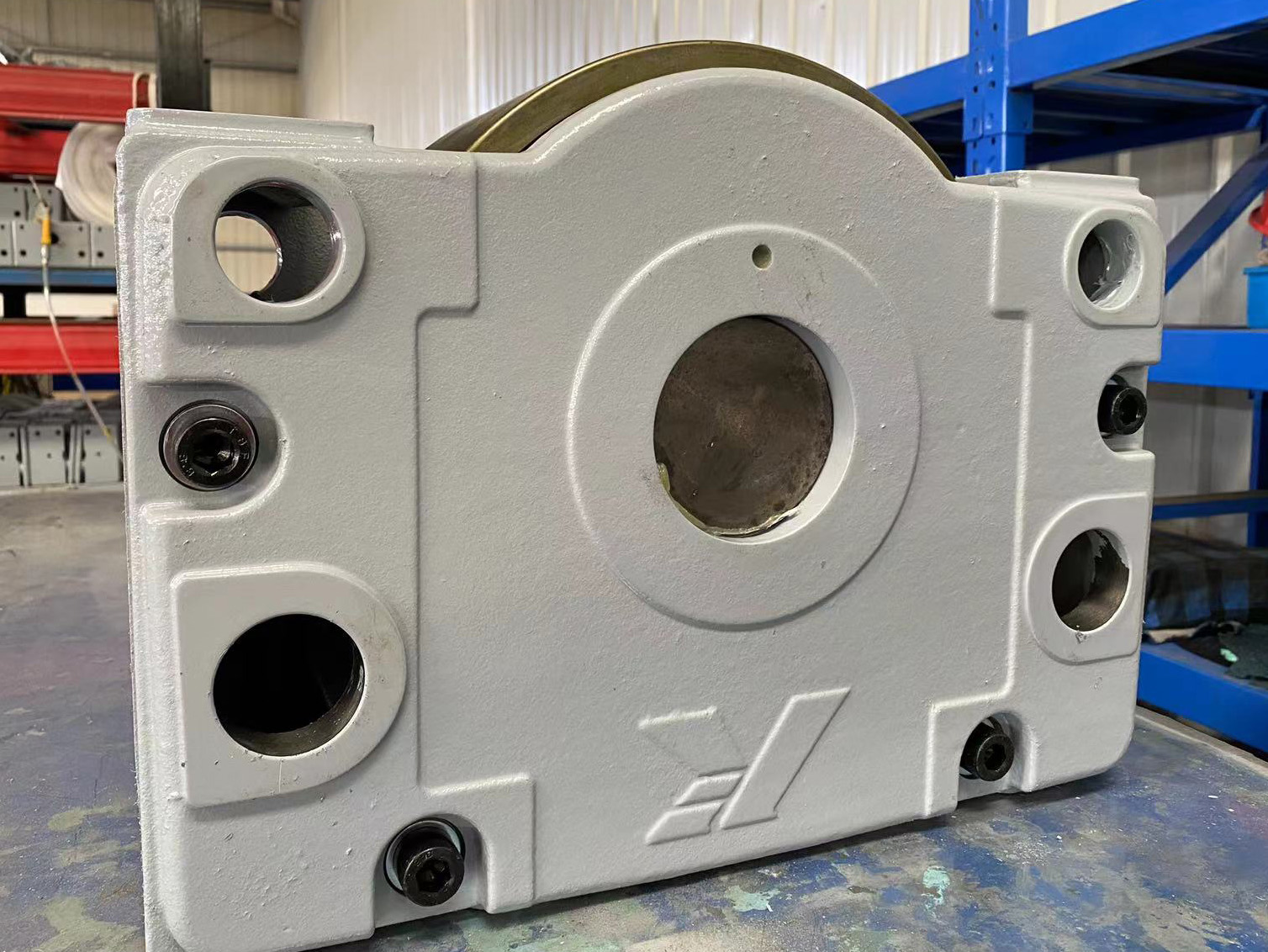

• Buffer: Solid buffer, spring buffer, hydraulic buffer, etc.

3. Emergency Stop Button: An emergency stop button is a crucial safety device that instantly stops all crane movements when pressed. It is usually located at easily accessible points on the crane and can be used in case of emergencies, malfunctions, or potential hazards.

4. Anti-Collision Systems: For the single overehad crane, they are used to lifting heavy loads on one side. So it's likely to collapse if there is not anti-collosion device. Crane operations often involve multiple cranes working in close proximity.

Anti-collision systems use sensors and advanced technology to detect the presence of other cranes or obstacles, and they automatically adjust the crane's movement to avoid collisions.

5. Load Moment Indicator (LMI): LMI provides real-time information about the crane's load moment, indicating whether it is within  safe operating limits. It helps operators make informed decisions during lifting operations and prevents tipping or instability due to overloading. For exmaple, our newly launched belt crane is monitored through industrial pad, which makes efficient lifting in ISO Class 5 cleanroom possible.

safe operating limits. It helps operators make informed decisions during lifting operations and prevents tipping or instability due to overloading. For exmaple, our newly launched belt crane is monitored through industrial pad, which makes efficient lifting in ISO Class 5 cleanroom possible.

6. Sway Control System: This system is designed to minimize load swing or sway during lifting and positioning operations. It uses sensors to detect any unwanted movement and applies counteracting forces to stabilize the load, reducing the risk of accidents caused by swinging loads.

Apart from the above crane safety device, swivel knob locking device, safety hook, rail clamping devices are also important devices to ensure operating safety. In addition to these safety devices, cranes should also have proper lighting, audible warning devices, and clear signage to enhance visibility and communication. Regular inspections, maintenance, and operator training are equally important to ensure that all safety devices are functioning correctly and being utilized effectively.

All the above safety devices can be installed on overhead crane, jib crane, gantry crane and various types of hoists. It is worth noting that the specific safety devices installed on a crane may vary depending on its type, size, and intended application. However, the fundamental goal of all safety devices is to minimize risks and create a safe working environment for crane operators in lifting operations.

KUNFENG CRANES can produce all crane solutions and products, from 1-ton single girder cranes to 100-ton double box girder cranes. We aim to offer high-value cranes with industry-leading lead times. Give us a chance, and we will exceed your expectations.