| Food Industry Clean Room Lifting Equipment

| Want to know more about Food Industry Clean Room Lifting Equipment?

Clean room lifting equipment usually refers to equipment used for cargo handling and lifting operations in clean rooms.

In the food industry, clean room lifting equipment usually refers to equipment used for cargo handling and lifting operations in clean rooms. These lifting equipment need to meet the requirements of clean room environment to ensure that they will not cause pollution to the food production environment.

The structure of the clean room crane:

● Main beam and cross beam: constitute the skeleton structure of the crane and support the overall weight of the crane and the weight of the lifted object. The main beam usually moves along the track of the work site, and the cross beam spans the main beam and is used to support the lifting mechanism of the crane.

● Lifting mechanism: It is the core component of the crane and is used to achieve lifting and handling operations. It usually includes a lifting mechanism, a cart mechanism and a trolley mechanism. The lifting mechanism is used to move the lifting object up and down, the cart mechanism is used to move laterally along the main beam, and the trolley mechanism is used to move laterally on the cross beam.

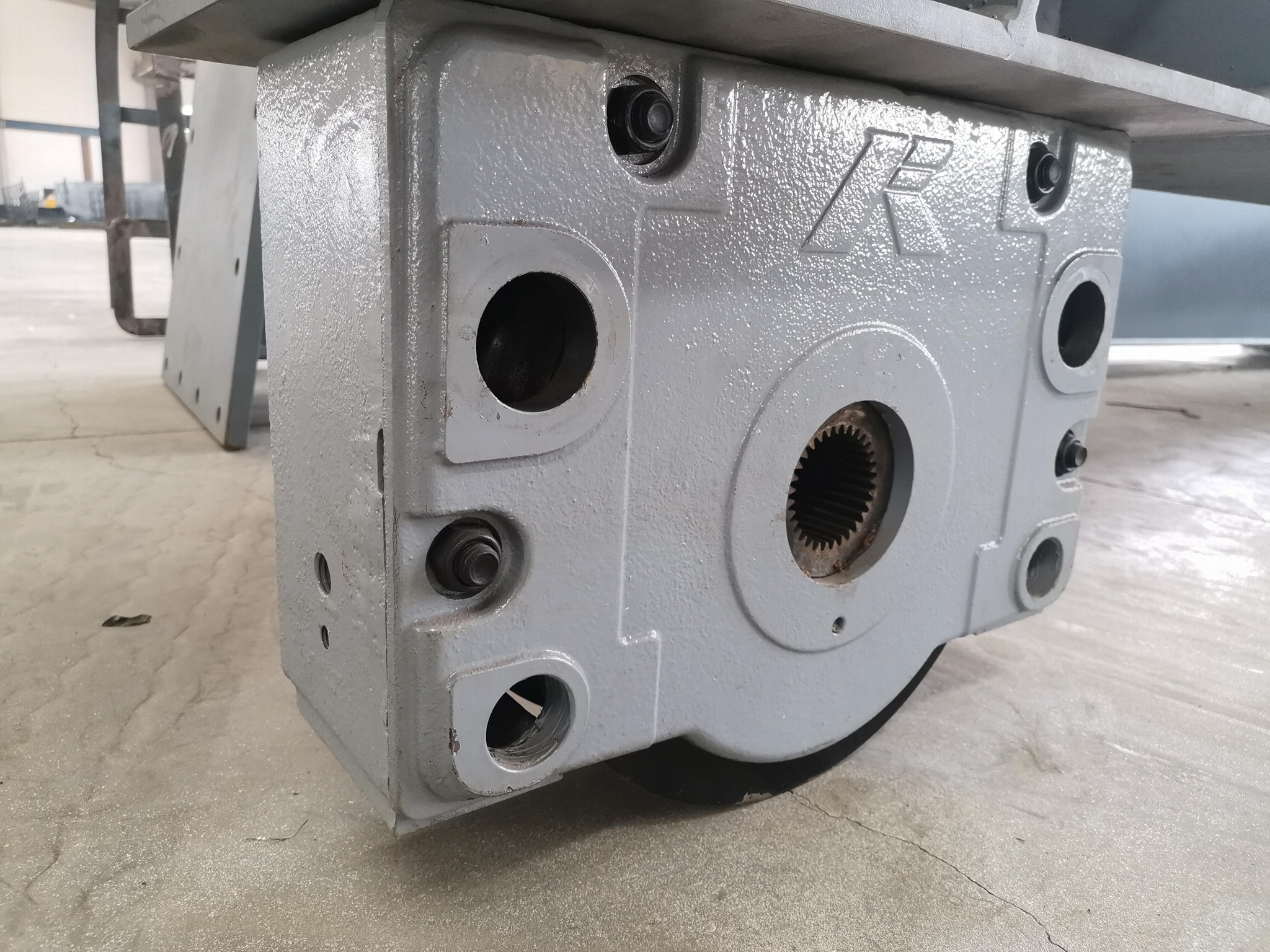

● Motor and transmission: Cranes are usually equipped with electric motors and corresponding transmissions to drive the movement of the lifting mechanism. The electric motor transmits power to the lifting mechanism through the transmission device to realize lifting and carrying operations.

● Control system: including the main operating console, electrical control cabinet, sensors, actuators and other components. It is used to monitor and control the operation of the crane, including starting, stopping, speed adjustment, position control and other functions.

● Safety protection devices: In order to ensure the safe operation of the crane, a variety of safety protection devices are usually equipped, such as limit switches, heavy-load protection devices, power-off protection devices, etc. These devices can stop the operation of the crane in time when unexpected situations occur, ensuring the safety of personnel and equipment.

● Wire rope or lifting chain: used to connect the lifting mechanism and the lifting object, transfer the lifting force, and realize lifting and transportation operations.

Features:

● Stainless steel material: In order to comply with the hygienic standards of the food industry, clean room lifting equipment is usually made of stainless steel, which can prevent rust and corrosion and ensure that the equipment does not contaminate food.

● Closed design: Clean room lifting equipment usually has a closed design to prevent dust, bacteria or other contaminants from entering the interior of the equipment, thereby ensuring air quality and hygiene standards inside the clean room.

● Safety performance: Clean room lifting equipment needs to have good safety performance, including safety protection devices, emergency stop buttons, etc., to ensure that the equipment will not cause harm to workers during operation.

● Clean and easy to clean: Clean room lifting equipment usually has a smooth surface and simple structural design, which facilitates cleaning and maintenance, ensuring that the equipment itself will not become a source of food contamination.

How to choose a clean room crane:

● Select equipment that complies with relevant regulations and standards to ensure its safety and reliability.

● Select the appropriate type and specification according to actual needs to ensure that its applicability and performance meet the requirements.

● Choose suppliers and service providers with good reputation and reputation to ensure reliable product quality and service quality.

● Select appropriate key components such as control systems and transmission systems according to actual needs to ensure stable and reliable performance.

● Consider the maintenance needs of the equipment and select equipment with easy maintenance features to reduce subsequent maintenance costs.

● Consider the price factor of the equipment and choose the appropriate equipment based on the actual budget to avoid unnecessary losses or risks caused by excessively high or low prices.