| Installation Method of KBK Light Suspension Crane

1. The key installation method of KBK track crane

1. The key installation method of KBK track crane

Generally speaking, there are two types of beams used for KBK track installation: steel frame structure beams and precast concrete beams. The latter must have holes for embedded parts. You can wear bolts or wear bolts during installation. The key to the installation method is the fixed pin method, the fixed screw of the hook-shaped extruder, the fixed fixed with electric welding and bolts. If the first method is used, it must have sufficient rigidity, and it can be made into a single hole or a double hole according to the supporting condition of each pin.

2. Installation of KBK rail specification components

The suspension of the track is a key specification component, which is usually located in the upper suspension beam or the track suspension frame, and can be installed with two long ball nuts. It must be noted that all bolts must be tightened with the required torque when connecting. Only then can the light rail be hung. After the hanger is installed, it is necessary to carry out the connection of the track. The bolts can be connected with a hexagon socket wrench containing a universal joint. The connection should ensure that the bolts are evenly tightened according to the specified torque. If the bolts are screwed on both sides If it is not as tight, it will cause the track to bend, and when the suspension is several tracks, it must pass through a plane, and if a parallel line. Even if there is a deviation, the horizontal aspect ratio cannot exceed 10mm.

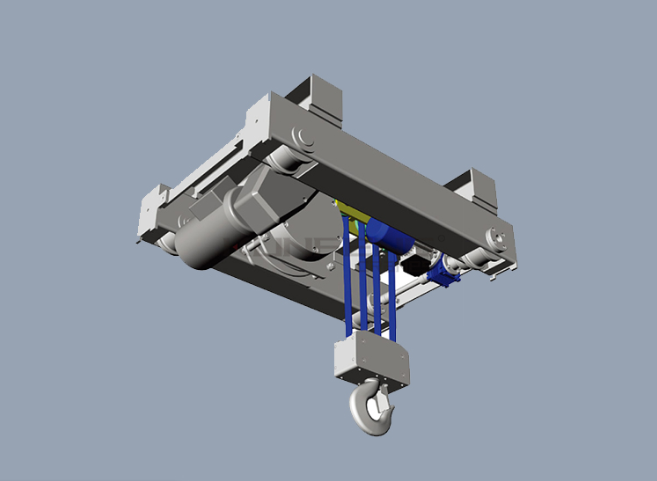

Next, the operating trolley, cable trolley and built-in buffer must be installed into the track. In order for the installation to be successful, the top of the track must be perforated, and the edge of the track must be closed with the bearing end cover of the buffer, and the bolts on the end cover of the ice crystal bearing of the specified torque are required to ensure the safe operation of the trolley.

Can be customized accroding to your needs.