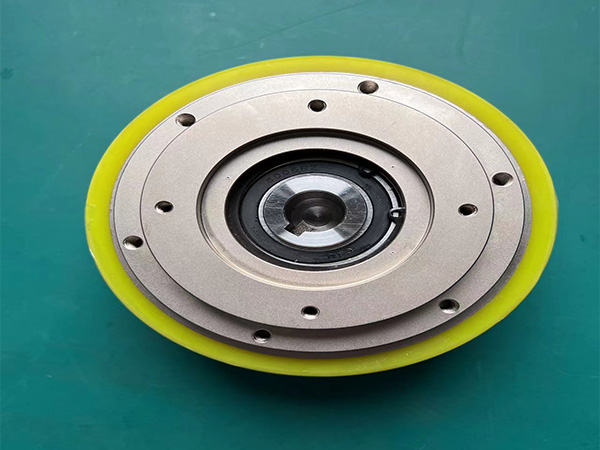

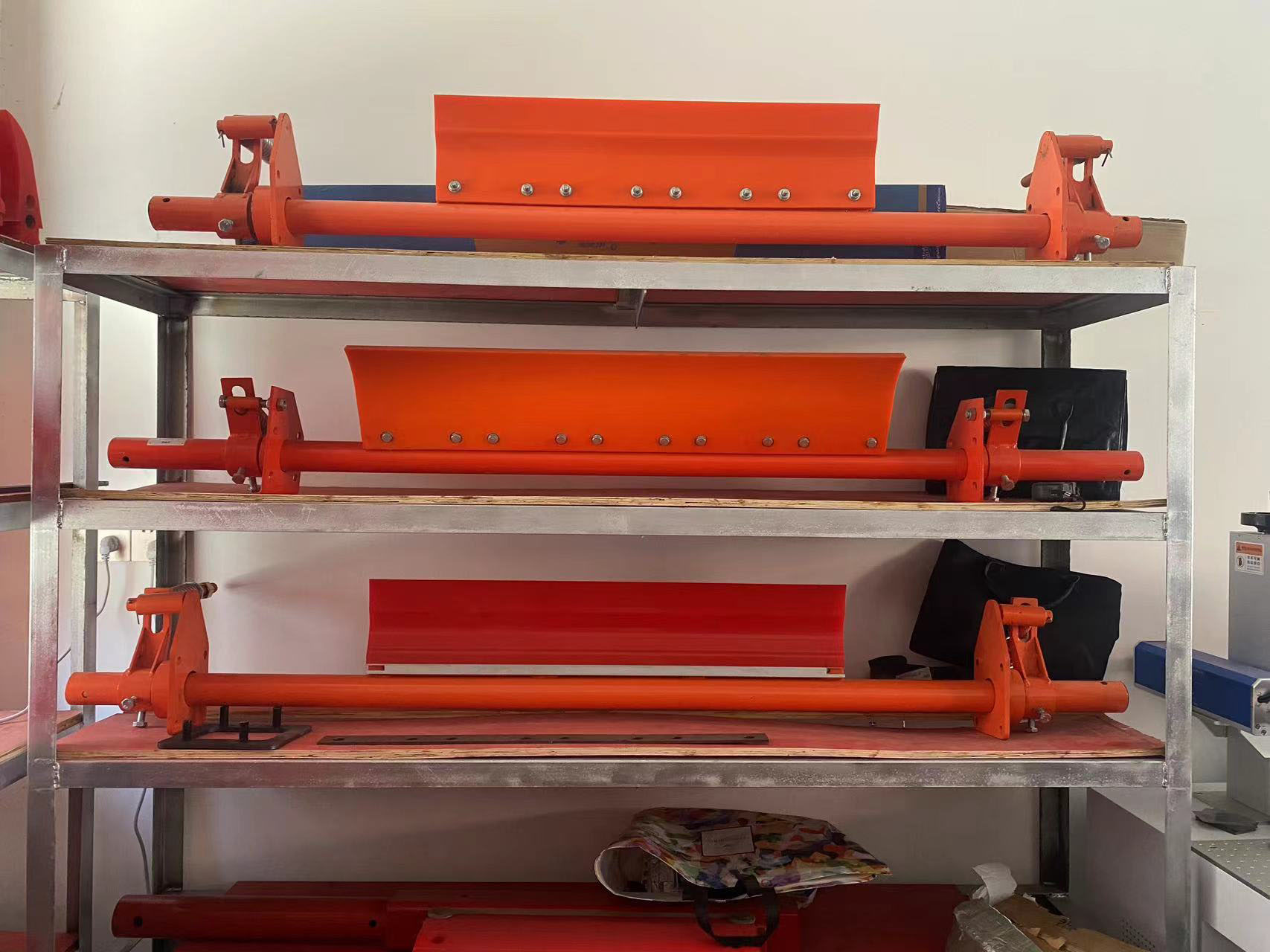

| The processing process of polyurethane coated rollers includes those steps

The processing process of polyurethane coated rollers.

CATEGORY:

CREATED:

Nov 27, 2020

1. Clean the surface of the product to be encapsulated: if it is a new product, you need to wash off the oil on the surface with a cleaning agent; if it is an old product, you need to remove the debris on the outer layer of the old product, and use the cleaning agent to remove the remaining surface The glue is cleaned.

2. The surface of the product is roughened: the surface of the product is roughened to increase the bonding area between the product surface and the encapsulation.

3. Sandblasting treatment: the rough-treated product is subjected to sandblasting treatment. Sandblasting will select different types of sand according to the material of the product for sandblasting. Sand blasting is to make the surface of the product rougher, and the glue will adhere to the product better after encapsulation.

4. Encapsulation: The products after the above treatment are encapsulated according to customer requirements.

5. Rubber-coated wheel vulcanization: The product after encapsulation generally needs a vulcanization time of 10-15 hours. After vulcanization, the product and the encapsulation will be closely bonded and the encapsulation will be formed.

6. Glue-coated grinding: Grind according to the size and shape of the customer's requirements. When some customers have high requirements on the surface of the rubber-coated product, they need to use a CNC grinder to polish the rubber-coated product.

Can be customized accroding to your needs.

2. The surface of the product is roughened: the surface of the product is roughened to increase the bonding area between the product surface and the encapsulation.

3. Sandblasting treatment: the rough-treated product is subjected to sandblasting treatment. Sandblasting will select different types of sand according to the material of the product for sandblasting. Sand blasting is to make the surface of the product rougher, and the glue will adhere to the product better after encapsulation.

4. Encapsulation: The products after the above treatment are encapsulated according to customer requirements.

5. Rubber-coated wheel vulcanization: The product after encapsulation generally needs a vulcanization time of 10-15 hours. After vulcanization, the product and the encapsulation will be closely bonded and the encapsulation will be formed.

6. Glue-coated grinding: Grind according to the size and shape of the customer's requirements. When some customers have high requirements on the surface of the rubber-coated product, they need to use a CNC grinder to polish the rubber-coated product.

Can be customized accroding to your needs.