| Electric Synthetic Fiber Rope Hoist Supplier

| Want to know more about Electric Synthetic Fiber Rope Hoist Supplier?

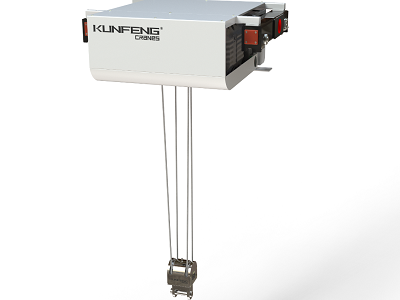

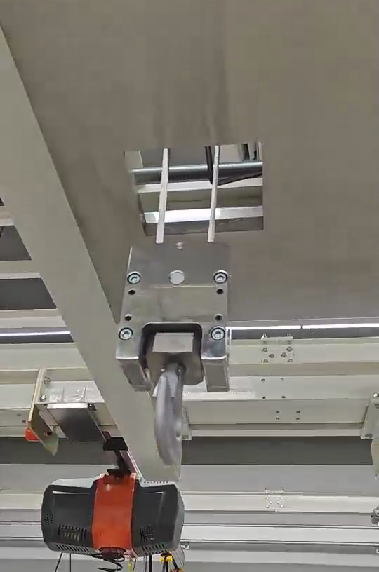

The electric synthetic fiber rope hoist is corrosion-resistant and fatigue-resistant, equipped with overload protection and limit switches. It is suitable for the lifting needs of bridge, gantry, cantilever jib and other lifting equipment.

The electric synthetic fiber rope hoist is an innovative material lifting equipment that combines modern material technology with traditional lifting technology. It replaces steel wire rope with high-performance synthetic fiber rope, supplemented by a compact electric drive unit, to achieve lightweight, safe and efficient lifting operations. This product is widely used in factory workshops, warehousing logistics, assembly lines and clean environments, and is an ideal supporting equipment for bridge cranes, gantry cranes and cantilever jib cranes.

Advantages of synthetic fiber rope hoists

● The synthetic fiber rope has a low density, which greatly reduces the weight of the hoist, reduces the burden on the track and drive mechanism, and improves the energy efficiency of the whole machine.

● It uses high-quality aramid or ultra-high molecular weight polyethylene fibers, which are specially woven and coated to have high tensile strength, fatigue resistance and corrosion resistance.

● Equipped with overload protection, upper and lower limit and emergency stop devices, multiple safety guarantees.

● No regular lubrication or anti-corrosion maintenance is required, there is no problem of wire rope breakage or rust, the maintenance cycle is long, and the maintenance cost is low.

● The fiber rope has low friction with the drum, low operating noise, and smooth start and stop, which is suitable for assembly or clean environments that are sensitive to noise and vibration.

Main technical parameters (for reference)

● Material: synthetic fiber

● Rated load: 500kg - 10000kg

● Lifting height: 3m - 12m (customizable)

● Lifting speed: 4m/min - 10m/min

● Motor power: 0.8-7.5kW (380V/50Hz)

● Control mode: handheld button/wireless remote control/PLC integration

● Protection level: IP54/optional IP65

Typical application scenarios

● Modern workshop: replace wire rope lifting, reduce bridge crane and track wear, and extend equipment life.

● Warehousing and logistics: lightweight lifting and positioning, optimize automated conveyor lines and sorting systems.

● Clean room/electronic assembly: low dust and noise, no metal debris, meet ISO clean standards.

● Assembly and maintenance stations: quickly hoist small equipment or components to improve operation convenience.

Selection suggestions

● Load and height requirements: Select appropriate load and fiber rope length according to operating weight and clearance.

● Operating frequency: For high-frequency use, it is recommended to select dual-speed or variable frequency control models.

● Environmental requirements: Special environments (high temperature, humidity, explosion-proof) require corresponding protection levels and materials.

If you need more technical information, selection support or customized solutions for electric fiber rope hoists, please contact us!

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151