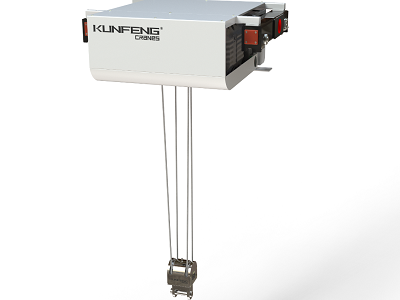

| Pharmaceutical Clean Room Cranes

Cleanroom cranes are suitable for the pharmaceutical industry because they are specially designed to maintain strict cleanliness standards. They use smooth, easy-to-clean materials, have advanced automated control systems to reduce human intervention, and are designed to prevent contaminants from entering the clean environment, thereby effectively reducing the risk of cross-contamination and ensuring the safety and quality of the pharmaceutical production process.

Operation mode

Pharmaceutical cleanroom cranes are lifting equipment designed specifically for cleanroom environments, and their operation strictly follows the operating procedures and standards of cleanrooms. Specifically, it uses power sources such as electric or hydraulic, and achieves lifting, handling, positioning and other operations through precise control systems. During operation, the crane needs to maintain a high degree of stability and precision to ensure the safety and accuracy of materials during handling.

Product advantages

● Special materials and designs are used to ensure that no dust and particles are generated during operation, meeting the pharmaceutical industry's requirements for high cleanliness.

● The crane's materials have been specially treated to have excellent wear and corrosion resistance, and can operate stably and for a long time in a pharmaceutical cleanroom environment.

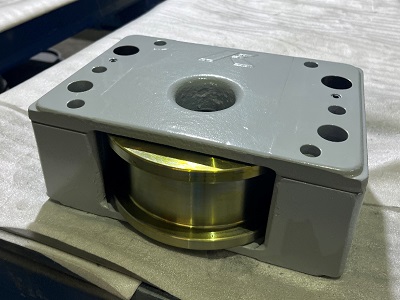

● The use of advanced control systems and transmission mechanisms ensures the stability and reliability of the crane, reduces the failure rate, and improves production efficiency.

● The crane has a wide speed regulation range and can adjust the operating speed according to actual needs to meet the needs of different work scenarios.

● Equipped with a high-precision positioning system, it can accurately position the material to the specified position to improve production accuracy and efficiency.

Clean room cranes are not only suitable for the pharmaceutical industry, but also widely used in other fields with high cleanliness requirements:

● In the semiconductor manufacturing process, clean room cranes are used to transport high-precision products such as wafers and chips to ensure the cleanliness of the production process and product quality.

● On the electronic assembly line, clean room cranes are used to transport electronic components, circuit boards and other materials to improve assembly efficiency and product quality.

● In the field of biotechnology, clean room cranes are used to transport biological samples, culture media and other materials to ensure the cleanliness of the experimental environment and the accuracy of experimental results.

● In the process of food processing and packaging, clean room cranes can be used to transport and position food raw materials, semi-finished products and finished products to ensure the hygiene and safety of food.