| What Materials Can be Used for Cleanroom Cranes

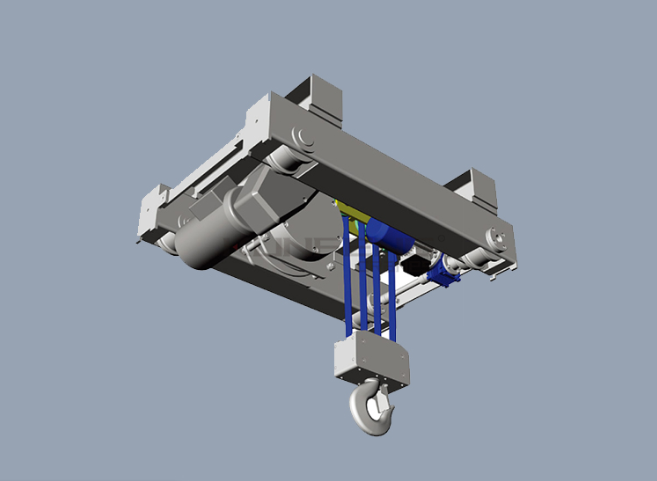

A cleanroom is an environment requiring a high level of cleanliness to ensure products are not contaminated during the manufacturing process. To maintain such high cleanliness, it is crucial to use materials that do not shed particles or cause pollution. When selecting materials for cleanroom cranes, several factors should be taken into account, including the material' s surface finish, ease of cleaning and corrosion resistance.

Stainless steel cranes are an excellent choice for lifting operations in cleanrooms, thanks to their smooth surfaces that are not prone to particle shedding. Stainless steel cranes also offer corrosion resistance, making them ideal for humid environments such as those in the food and chemical industries. Grade 304 stainless steel is the most commonly used material for cleanroom cranes, and it is widely applied in the production environments of the pharmaceutical and medical industries.

Coated steel cranes represent another option for cleanrooms, though they are less ideal than stainless steel alternatives. While steel is robust and durable, its surface finish is not as smooth as that of stainless steel, meaning it is more likely to shed particles. In addition, coated steel requires frequent maintenance to prevent corrosion and ensure consistent suitability for cleanroom use. Therefore, if a steel structure is adopted, protective measures such as stainless steel cover sealing must be implemented to avoid particle shedding.

Aluminum alloy cranes feature a high-strength aluminum structure with advantages including light weight, low particle emission, corrosion resistance, dust accumulation resistance and easy cleanability. They are particularly suitable for scenarios with stringent cleanliness requirements, such as semiconductor manufacturing, biopharmaceutical production, optical component fabrication and laboratories. The inherent non-magnetic property and low-friction surface of aluminum reduce contamination risks during operation. Meanwhile, the significantly reduced equipment weight facilitates installation, movement and modular expansion, delivering a material handling solution for clean spaces that boasts higher efficiency and lower contamination risks.

When choosing materials for cleanroom cranes, the operating environment of the crane must also be considered. For instance, if the crane will be used in a humid environment with corrosive liquids, stainless steel cranes and hoists are the optimal choice. In less demanding environments such as research institutes, laboratories and other dry settings, steel cranes with proper protective measures are acceptable. For lifting light loads in cleanrooms, aluminum alloy cranes are a viable option. Beyond selecting suitable materials, adhering to cleanliness best practices is also critical. This includes keeping the crane clean, removing debris, using appropriate cleaning agents and conducting regular maintenance to prevent corrosion and other surface defects.

KUNFENG CRANES is a leading manufacturer of cleanroom cranes in China, specializing in the design and production of high-quality cleanroom lifting equipment. Click to contact us for customized cleanroom material handling solutions tailored to your production applications, we will help you achieve safe, stable and reliable operations.