| Maintenance and Inspection for Overhead Bridge Crane | China Factory

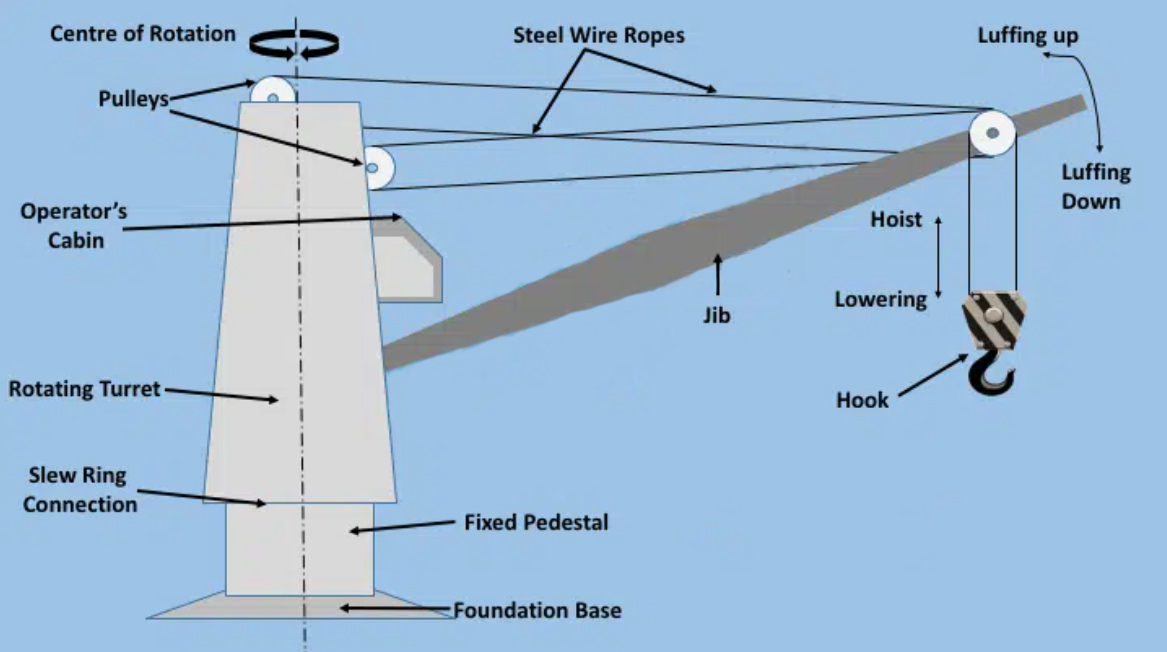

Overhead crane is a common lifting equipment consisting of a single girder or two parallel beams used to transport cargo from place to place inside a factory, warehouse, garage. Cranes are heavy and dangerous machines. They should only be operated by people who have been properly trained and who take all necessary safety precautions. Even a small mistake can cause serious injury or damage.

Overhead crane is a common lifting equipment consisting of a single girder or two parallel beams used to transport cargo from place to place inside a factory, warehouse, garage. Cranes are heavy and dangerous machines. They should only be operated by people who have been properly trained and who take all necessary safety precautions. Even a small mistake can cause serious injury or damage.

Why crane inspection and maintenance are important?

Overhead cranes are complex machines that can be dangerous if not properly maintained. By inspecting and maintaining your crane regularly, most accidents and injuries can be avoided. In addition, routine inspections of bridge cranes and crane hoists can help identify problems early on, so that corrective action can be taken before they cause a major accident or require expensive and time-consuming repairs.

What should you do when performing maintenance of a crane?

1. Pre-check for Crane Inspection

A pre-check for overhead crane inspection is a brief inspection that is performed before the crane is used. The purpose of the pre-check is to identify any potential hazards that could prevent the crane from being used safely. The pre-check should include the following steps:

· Visually inspect the crane for any obvious damage of defects.

· Inspect the lifting cables and chains of overhead cranes for any signs of wear or damage.

· Make sure that crane's work area is clear of any obstructions.

· Make sure the operator is trained on all aspects of crane use, including the functional limitations of the equipment. These professionals can thoroughly examine even the most complex parts of the crane to guarantee safety, reliability, compliance, and conformity with statutory requirements and crane inspection regulations.

2. Major inspection for cranes

* Frequent inspection:

Frequent crane inspections are conducted daily or monthly, depending on the frequency of use. These inspections typically cover air or hydraulic system components, operating mechanisms, hooks, and hoist chains. Some items must be inspected daily before each shift. For Example:

Frequent crane inspections are conducted daily or monthly, depending on the frequency of use. These inspections typically cover air or hydraulic system components, operating mechanisms, hooks, and hoist chains. Some items must be inspected daily before each shift. For Example:

1). Check that the wear amount of the brake pad liner should not exceed 2mm, and the contact area between the liner and the brake wheel should not be less than 70%; check the installation and fixation of each pin shaft and the wear and lubrication conditions, and the wear amount of each pin shaft It should not exceed 5% of the original diameter, and the wear of the small shaft and mandrel should not exceed 5% of the original diameter and the ellipticity should not be less than 0.5mm.

2). Check the wear and tear of the wire rope, whether there are broken wires, etc., and check the lubrication of the electric wire rope hoist.

3). Check whether the hook has cracks, whether the wear of the dangerous section exceeds 5% of the original thickness; whether the anti-loosening device of the hook nut is complete, and whether each part on the hook group is complete and reliable. The hook should rotate flexibly without jamming.

4). Check all bolts for looseness and shortage.

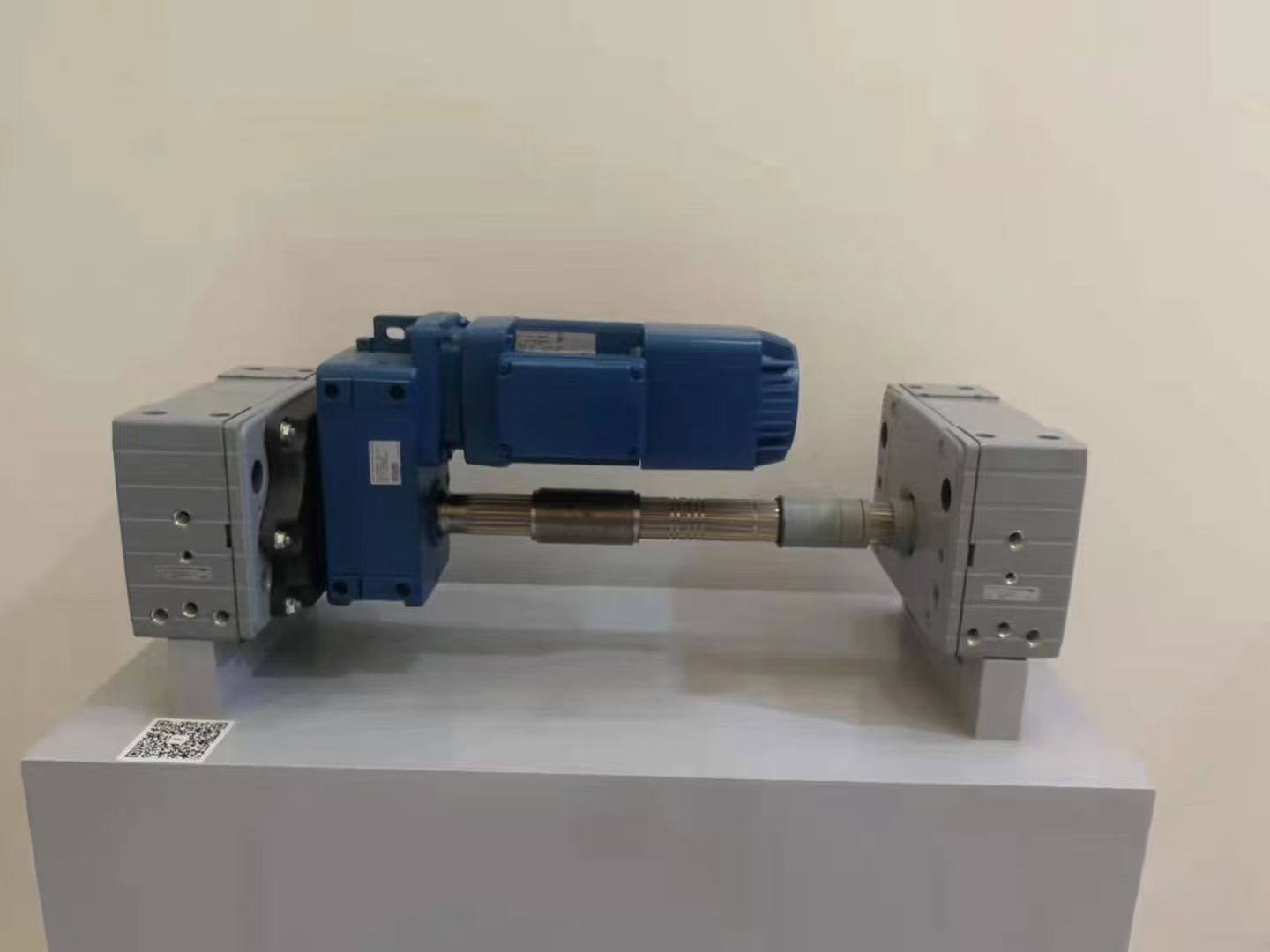

5). Check the bolt fastening of the motor, reducer and other bases, and tighten them one by one.

6). Check the lubrication condition of the reducer, the oil level should be within the specified range, and measures should be taken to prevent leakage at the oil leakage parts.

7). Lubricate the gears.

8). Check the wear of the wire rope at the balance pulley and lubricate the pulley and the pulley shaft.

9). Check the condition of the pulley to see if it is flexible, whether it is damaged or cracked, and pay special attention to the wear of the fixed pulley shaft.

10). Check the brake wheel, the unevenness of its working surface should not exceed 1.5mm, the brake wheel should not have cracks, and its radial circular runout should be less than 0.3mm.

11). Check the coupling, the upper key and keyway should not be damaged or loose; the axial serial momentum of the transmission shaft between the two couplings should be 2~7mm.

12). Check the operation status of trolley and end carriage, and there should be no phenomena such as rail gnawing, three fulcrums, twisting when starting and stopping. Check the wear of the rim and tread of the wheel. The wear of the rim thickness should not exceed 50% of the original thickness, and the wear of the wheel tread should not exceed 3% of the original diameter of the wheel.

13). Check the condition of the end carriage track to see if the bolts are loose or short, whether the pressure plate is fixed on the track, whether the track is cracked or broken; whether the gap between the two track joints is 1~2mm (Summer) or 3~5mm (Winter), whether the vertical and horizontal misalignment of the joint exceeds 1mm.

14). Carry out a comprehensive cleaning of the crane.

15). And other abnormal situations, etc.

* Periodic inspection

* Periodic inspection

While periodic crane inspections emphasize smaller parts that are often missed during routine inspections. Periodic crane inspections pay special attention to:

·Chain overstretch

·Loose rivets and bolts

·Worn wheels and

·Aging or malfunctioning electrical components such as push button stations, limit switches and control contractors

·Bearing deformation

·Wear of the brake and clutch system

·False readings and inaccurate indicators

·Faulty and unsafe power plants

Meanwhile, remember to keep record for maintenance and inspection. For some special overhead cranes, such as inspect the stainless steel housing of clean room overhead cranes for corrosion and check safety devices of explosion-proof overhead cranes.

3.Designing a Custom Crane Inspection and Maintenance Schedule

Overall, every crane should have a custom inspection and maintenance plane. A custom suitable maintenance plan helps to improve safety for employees and other people on-site. Contact KUNFENG CRANES to get a tailored-made service.