| Choosing the right polyurethane material can also increase the friction of the polyurethane bearing wheel

Polyurethane bearing wheels to increase friction.

CATEGORY:

CREATED:

Dec 25, 2020

Polyurethane bearing wheels to increase friction

1. Reduce the hardness of the polyurethane elastomer of the polyurethane wheel, and the polyurethane hardness range is wider. If you want to increase the friction of the wheel, you can choose a polyurethane composite material with lower hardness requirements for encapsulation when the load capacity is satisfied. After the low-hardness wheel is compressed, the deformation becomes larger, and the contact building area with the contact surface becomes larger, and the friction force of the wheel becomes larger.

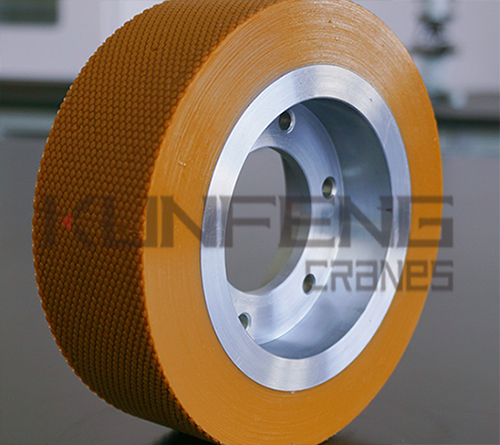

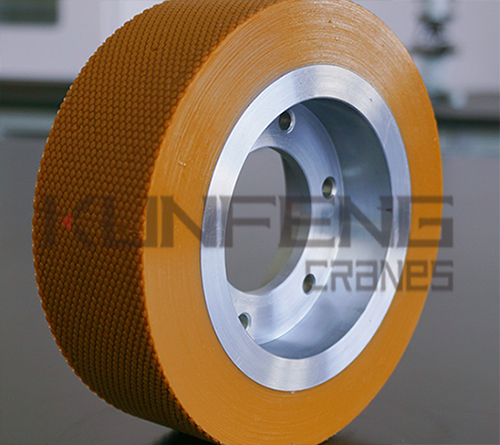

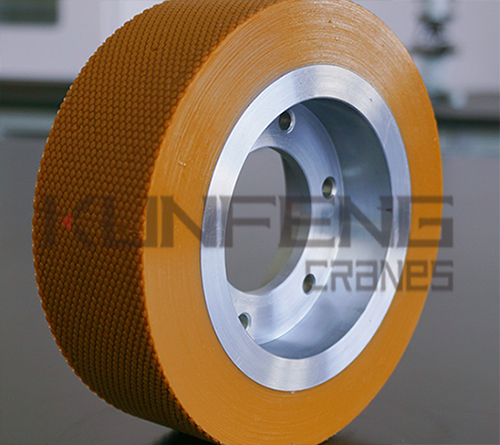

2. Knurling or hair processing is applied to the polyurethane wheels, and increasing the surface roughness of the wheels can make the wheels have good friction and will not slip during use. Currently, there are many ways to make patterns or hair on the surface of wheels. 3. The width of the wheel is increased, so that the area of direct contact with the contact surface becomes larger. After the wheel width is increased, the contact area between the wheel itself and the contact surface during use continues to increase, and the friction force increases accordingly. 4. Directly increase the vertical load of the wheels (equipment pressurization). By continuously increasing the direct load of the equipment, the vertical load received by the wheel is increased, thereby increasing the deformation of the wheel and increasing the friction. 5. Use polyurethane raw materials with higher adhesion between molecules and contact surfaces to make finished wheels. As a synthetic material, polyurethane has very different physical and chemical properties, and the adhesion (stress) between different materials and contact surfaces is also different. The selection of suitable polyurethane materials can also increase the friction of the polyurethane load-bearing wheels.

Can be customized accroding to your needs.

1. Reduce the hardness of the polyurethane elastomer of the polyurethane wheel, and the polyurethane hardness range is wider. If you want to increase the friction of the wheel, you can choose a polyurethane composite material with lower hardness requirements for encapsulation when the load capacity is satisfied. After the low-hardness wheel is compressed, the deformation becomes larger, and the contact building area with the contact surface becomes larger, and the friction force of the wheel becomes larger.

2. Knurling or hair processing is applied to the polyurethane wheels, and increasing the surface roughness of the wheels can make the wheels have good friction and will not slip during use. Currently, there are many ways to make patterns or hair on the surface of wheels. 3. The width of the wheel is increased, so that the area of direct contact with the contact surface becomes larger. After the wheel width is increased, the contact area between the wheel itself and the contact surface during use continues to increase, and the friction force increases accordingly. 4. Directly increase the vertical load of the wheels (equipment pressurization). By continuously increasing the direct load of the equipment, the vertical load received by the wheel is increased, thereby increasing the deformation of the wheel and increasing the friction. 5. Use polyurethane raw materials with higher adhesion between molecules and contact surfaces to make finished wheels. As a synthetic material, polyurethane has very different physical and chemical properties, and the adhesion (stress) between different materials and contact surfaces is also different. The selection of suitable polyurethane materials can also increase the friction of the polyurethane load-bearing wheels.

Can be customized accroding to your needs.