| Installation of Aluminum Rail Workstation Bridge Crane

Aluminum rail workstation bridge crane is a light crane with aluminum alloy rail as the core load-bearing structure and bridge structure. It usually has a lifting capacity of 0.5-10 tons and is designed for workshop environments with frequent handling and high-precision positioning. With its lightweight design, corrosion resistance and precise control capabilities, it is widely used in precision manufacturing, electronic assembly, new energy production lines and other scenarios. Correct installation can not only ensure its long-term stable operation, but also maximize the performance of the equipment.

Site survey and preparation before installation

Site leveling and load-bearing inspection

● Ensure that the ground or load-bearing beam surface is flat and solid, without cracks and obvious settlement.

● Calculate the bearing capacity of the foundation or superstructure based on the total weight and maximum load of the equipment, and reinforce the load-bearing beam or foundation if necessary.

Environmental and space assessment

● Measure the net height, span and walking area of the workshop, and reserve sufficient maintenance, inspection and safety passages.

● Confirm that there are no obstacles and high temperature/strong corrosive media in the installation area to avoid affecting the life of the aluminum rail and electrical components.

Tools and materials preparation

● High-precision measuring and tightening tools such as level, laser rangefinder, torque wrench, etc.

● Tightening bolts, locating pins, lubricating oil, cable tray and other supporting materials.

Aluminum rail pre-installation and precise positioning

Track assembly

● Assemble the aluminum rail segments according to the design drawings, fix them with locating pins and then tighten them with bolts.

● During the assembly process, keep the end faces of the rails at the same level, and the cumulative error does not exceed ±1mm.

Horizontal and vertical correction

● Use a laser level to measure the aluminum rails at multiple points, and gradually adjust the support blocks or gaskets to ensure that the horizontality of the entire track reaches ±0.5mm/10m.

● Check the verticality of the track and the workshop floor or beam surface to ensure operational safety.

Bridge and electric hoist installation

Bridge hoisting and alignment

● Use auxiliary hoisting equipment to lift the main bridge to the bottom of the track, slowly put it in place and slightly adjust it to make the bridge wheels aligned with the aluminum rails.

● Ensure that the bridge is not stuck or jumping when it is running on the track, and check whether the wheelbase and track gap meet the requirements of the equipment manual.

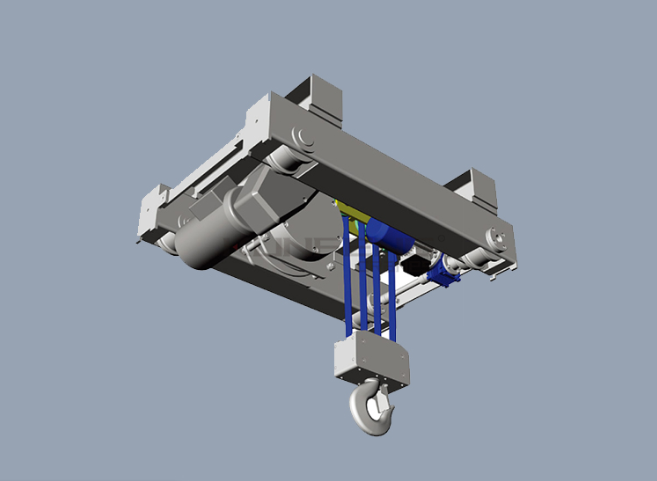

Installation of electric hoist and trolley

● Combining the electric hoist assembly with the trolley chassis, fix it with high-strength bolts.

● Hang the trolley on the crossbeam under the bridge, and use the regulator to correct the verticality of the hoist chain or wire rope so that the hook can be lifted and lowered smoothly under the bridge.

Electrical and control system wiring

Power supply and grounding

● According to the electrical design drawing, lay the power cable to the distribution cabinet, and do a good job of grounding and lightning protection.

Control circuit installation

● Arrange the button busbar or protective cable, and connect the lifting, running and emergency stop buttons to the main control system through the electrical cabinet.

● Optional remote control or intelligent PLC control, equipped with electronic limit switches, overload protection relays and other safety modules.

Trial operation and parameter debugging

No-load trial operation

● After the first power-on, first perform no-load operation to check the response sensitivity and braking distance of the lifting, walking and braking systems.

Full-load performance test

● Gradually increase the weight to the rated load to verify whether the lifting speed, braking effect and safety protection action are correct.

● Measure the actual operating noise and vibration to ensure that they are within the range of the equipment manual.

Through scientific and standardized installation processes and regular maintenance, aluminum rail workstation cranes can achieve efficient and smooth material handling in a narrower space, providing reliable lifting support for corporate production lines. If you need more technical support or customized services, please contact our professional team!