| What are Electric Overhead Travelling (EOT) Cranes

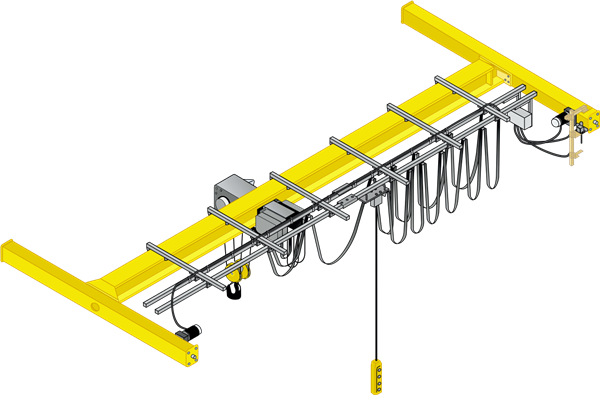

Electric overhead traveling cranes (EOT Cranes) are cranes suspended on the upper track of the workshop. They move horizontally along a single or double main beam through an electric hoist. The main beam can also move longitudinally on the tracks on both sides of the factory to cover the entire operation area. They are widely used in factory workshops, warehousing logistics and heavy assembly fields. They have the characteristics of high degree of automation, large load-bearing capacity and stable operation.

Main components of EOT cranes

● Bridge (main beam and end beam): carries the hook and lifting mechanism, and moves on the tracks on both sides of the factory;

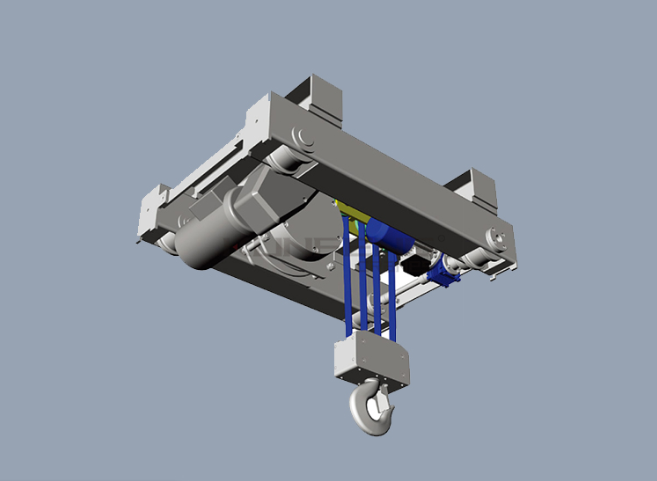

● Lifting mechanism (electric hoists): completes the vertical lifting and lowering of heavy objects;

● Transverse trolley: installed at the bottom of the main beam, carries and drives the lifting mechanism to move along the main beam;

● Longitudinal movement system: drives the entire bridge to move on the longitudinal track of the factory;

● Electrical control system: includes main power supply, control cabinet, button box or remote control device, as well as safety protection devices such as limit and overload.

Working principle of EOT cranes

● Hoisting: The lifting mechanism drives the hook to move vertically up and down to complete the lifting and lowering of goods.

● Trolley Travel: The trolley moves left and right on the bridge main beam to accurately locate the position of the hook in the width direction of the workshop.

● Bridge Travel: The entire crane travels on the track along the length of the workshop, covering the entire working area.

Design advantages of EOT cranes

● The main beam span can reach tens of meters, and the rated load ranges from 1 ton to 100 tons, meeting the needs of heavy material handling.

● Equipped with frequency conversion control, it can achieve smooth stepless speed regulation of start, run and stop, and the lifting accuracy is extremely high, especially suitable for scenes with high precision assembly or high positioning requirements.

● The coverage area is large and the lifting height is high, which significantly improves the material handling efficiency and reduces manpower dependence and handling time.

● Running on the track above the workshop, it hardly occupies the ground working space, maximizing the use of the height and area of the plant.

● Hooks, electromagnetic suction cups, grabs, special lifting tools, etc. can be selected according to different working conditions, covering a wide range of working levels.

● Equipped with multiple safety devices, strictly follow the safety design specifications to ensure the safety of personnel and equipment.

Typical application scenarios

● Metallurgy and heavy industry: lifting and transporting of overweight parts such as steel billets, castings, and machine tool bases.

● Automobile manufacturing and assembly: precise handling and line change of engines, frames, and body assemblies.

● Electric and nuclear power equipment: lifting of generator sets, turbine blades, and nuclear reactor components.

● Warehouse and logistics center: high-density material transfer between pallets, containers, and heavy-duty shelves.

Electric overhead traveling cranes (EOT Cranes) have become an indispensable key equipment in modern industrial production and logistics systems due to their large span, high load capacity, high space utilization, and high degree of intelligence. Want to know the EOT cranes solution that best suits your workshop? Welcome to contact our technical team for free customized consultation!