| Multi Fulcrum Suspension Overhead Crane

| Want to know more about Multi Fulcrum Suspension Overhead Crane?

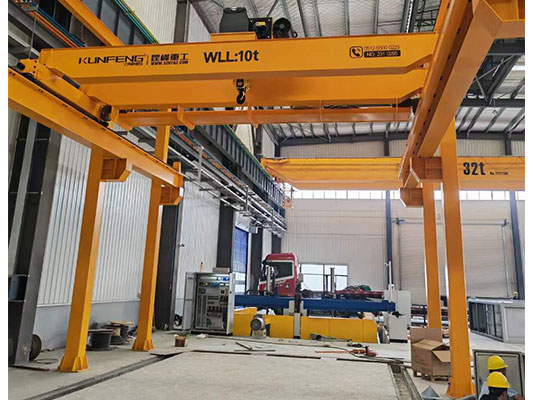

Multi fulcrum suspension overhead crane is a kind of lifting equipment which distributes the bridge through multiple suspension fulcrums on the upper load-bearing structure of the factory building or special rails.

Multi fulcrum suspension overhead crane is a kind of lifting equipment that distributes the bridge frame on the upper load-bearing structure of the factory building or on a special track through multiple suspension fulcrums. Compared with the traditional overhead crane with a single suspension point, it can evenly distribute the load to multiple support points, significantly reduce the deflection of the main beam and the deformation of the structure, so that it can still maintain a stable and accurate operation state under super-large span and heavy load conditions. This equipment is suitable for scenes with limited net height of the factory building, tight ground space or the need to cross complex structures, fully meeting the efficient handling needs of modern workshops, warehouses and assembly lines.

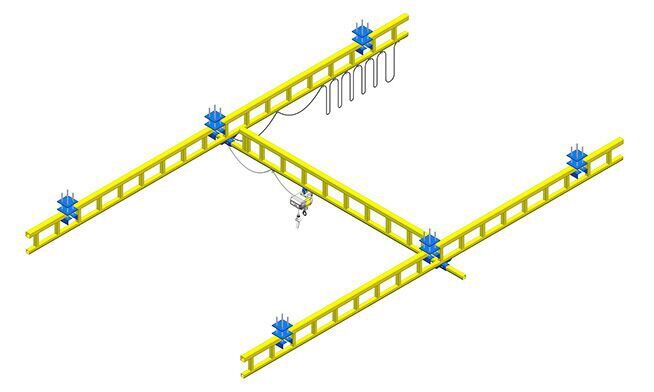

Structural composition of multi fulcrum suspension crane

● Multi fulcrum suspension bridge: The bridge frame is composed of high-strength I-beams or H-shaped welded steel beams, and the span can be customized from 10 meters to 30 meters or even larger.

● Suspension support device: Each support device is equipped with sealed bearings and can be equipped with fine-tuning screws to ensure that the height of the suspension points is consistent and the force is evenly distributed.

● Travel mechanism: The lifting trolley travels horizontally under the bridge frame and is equipped with an electric hoist or chain hoist to achieve vertical lifting.

● Electrical and control system: PLC + touch screen system is adopted, which can preset multiple groups of operating conditions, speed parameters and limit protection.

● Safety protection device: The two ends of the bridge and the lifting mechanism are equipped with travel limit switches to prevent overshoot; equipped with mechanical or electronic overload limiters to ensure transportation safety.

The main advantages of multi fulcrum suspension crane

● Multiple support points disperse the load, and the bridge can achieve a larger span and greater load-bearing capacity without easy deformation.

● The suspension design does not require ground rails or column support, the workshop floor remains clean and flat, and auxiliary equipment such as forklifts and AGVs can pass more flexibly.

● The suspension support points can be flexibly positioned and added according to the factory structure layout.

● Distribute the weight of the bridge to multiple bearing points to reduce the load pressure on a single beam and avoid large-scale reinforcement of the upper structure.

● Frequency conversion speed regulation and slow start/slow braking technology improve the horizontal and vertical walking and lifting accuracy, and can meet the positioning requirements of ±10 mm level.

Typical application scenarios

● Aerospace: accurate lifting and positioning of large components in aircraft assembly and maintenance hangars.

● Heavy industry: manufacturing workshops for large power generation equipment, rail transit vehicles, ship sections, etc.

● Logistics warehousing: ultra-large automated stereoscopic warehouses, material in and out of the warehouse and regional transfer in distribution centers.

● Special workshops: professional workshops that require large unobstructed working areas (such as wind tunnels, large test benches).

Multi fulcrum suspension overhead crane can not only meet the heavy-load lifting needs under various complex working conditions through reasonable structural design, precise force analysis and intelligent control, but also greatly improve the space utilization rate and production efficiency of the workshop. Welcome to contact us for free customized handling solutions!

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151