| Single Girder Underhung Overhead Crane Manufacturer

| Want to know more about Single Girder Underhung Overhead Crane Manufacturer?

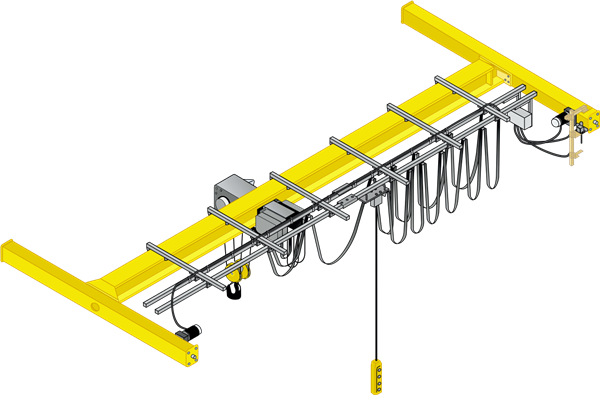

A single girder underhung overhead crane is a type of bridge lifting equipment in which the hoist runs under the main beam, used for vertical lifting and lateral handling within a factory building.

A single girder underhung overhead crane, also known as an under-running crane or underslung crane, is a type of overhead crane where the bridge girder is positioned beneath the runway or support structure. It is designed to provide lifting and material handling capabilities in situations where there are space limitations or specific operational requirements.

Overhead cranes are used for heavy duty application, up to 200 ton. A crane girder is a preformed metal beam on which the crab or hoist head of a traveling overhead crane runs. A single girder overhead crane is a type of bridge crane that consists of two overhead runways built into the building's support structure.

For the single girder crane, there is a end truck on each side for supporting the girder beam.

ADVANTAGES:

• Less expensive: Due to a simpler trolley design, reduced freight costs, simplified and faster installation, and less material for the bridge and runway beams.

• Space-saving design: Different with double girder bridge crane, the underhung configuration of the crane allows for efficient use of space, as the crane does not require additional height clearance above the runway. This makes it suitable for facilities with low ceilings or limited headroom.

• Easy to install and maintain: Single girder underhung cranes can be installed on new or existing support structures. They can be customized to fit specific layout requirements, and the runway beams can be suspended from the building structure or supported by free-standing columns.

Heavy duty overhead crane is a powerful piece of machinery found in steel mills, foundries, heavy machine shops, chemical plants and warehouses.

Technical Parameter | |

Capacity (ton) | 15 |

Span (m) | 31.5 |

Lifting Height (m) | 9 |

Working Class | A5,2M |

Lifting Speed (m/min) | 5/0.8 |

Trolley Weight (kg) | 400-750KG |

Crane Power (kw) | 4~12 |

Note:

• The crane standard travelling speed for 5~25m/min, while the trolley standard speed is 5~20m/min, both are in variable frequency control.

• Control options: Pendant switch, Remote control, or Cabin.

• Technical parameters only for reference. Want more specifics? Please email to sale@kfqizhongji.com.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151