| Bespoke Printing Rollers With PU Coating

| Want to know more about Bespoke Printing Rollers With PU Coating?

Polyurethane (PU) coated printing rollers are essential components in offset printing machines, designed to provide superior performance in terms of durability, ink adhesion, and print quality.

Polyurethane (PU) coated printing rollers are essential components in offset printing machines, playing a crucial role in the ink transfer and printing process. These rollers are specifically designed to provide superior performance in terms of durability, ink adhesion, and print quality. Here’s a detailed look at customized PU coating rollers for offset printers and why they are preferred in the printing industry:

Key Features of PU Coated Rollers

1. High Durability: Polyurethane coatings offer excellent wear resistance, which is crucial in the high-stress environment of a printing press where rollers are subjected to continuous contact and pressure.

2. Ink Adhesion: The PU coating facilitates better ink adhesion compared to other materials. This ensures a consistent and even ink distribution, resulting in high-quality prints.

3. Chemical Resistance: Polyurethane coatings are resistant to solvents, oils, and other chemicals commonly used in the printing process. This property prevents degradation of the roller surface, maintaining its integrity and prolonging its lifespan.

4. Temperature Stability: PU coated rollers can maintain their performance over a wide range of temperatures, which is beneficial in varying environmental conditions and during the heat of the printing process.

5. Low Moisture Absorption: The low moisture absorption of polyurethane ensures that the roller dimensions remain stable, preventing any dimensional changes that could affect print quality.

6. Smooth Surface Finish: The smooth surface of PU coated rollers ensures clean and crisp prints by preventing ink buildup and ensuring uniform ink transfer.

Specification of PU offset Printer Rollers

size | According To Customer's Drawing |

Length Dimension | Length:50MM-8200MM |

Material | Polyurethane |

Hardness | 18-100A |

Tolerance | 0.05mm |

Temperature | According customers's requirements |

Color | Customized:red, black, white, clear, etc |

Roll Core | Stainless steel,45#steel or 20#steel or 5#aluminum seamless pipe |

Applications in PU offset Printer Rollers

PU coated rollers are used in various parts of an offset printing machine, including:

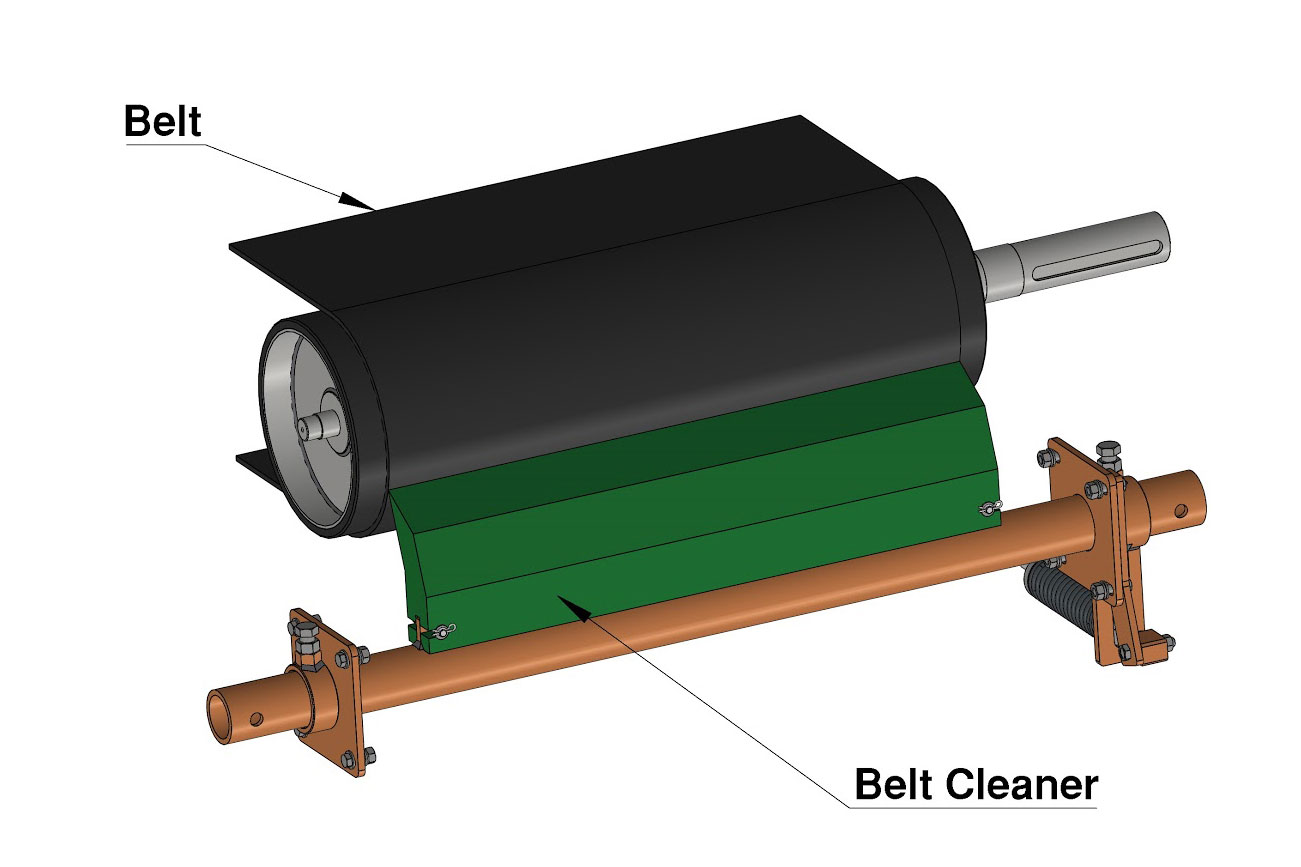

•Inking System: Ink rollers transfer ink from the ink fountain to the printing plate, ensuring a consistent layer of ink.

•Plate Cylinder: The roller that holds the printing plate, where ink is transferred from the ink roller to the plate.

•Blanket Cylinder: The roller that carries the inked image from the plate cylinder to the paper or substrate.

•Impression Cylinder: The roller that applies pressure to ensure the ink adheres to the substrate.

Conclusion

Polyurethane coated rollers are a vital component in offset printing technology, enhancing the efficiency and effectiveness of the printing process. Their superior properties ensure that they deliver high-quality prints while offering longevity and ease of maintenance, making them a preferred choice for professional printing environments. Whether it’s in commercial printing presses or in specialized printing applications, PU coated rollers play a critical role in achieving optimal print outcomes.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151