| 2 ton Cleanroom Overhead Crane in Lithium Battery Industry

The demand for lithium iron phosphate is on the rise, thanks to the increasing production and sales of new energy vehicles, and the growing installed capacity of their batteries. This demand is expected to continue growing as the sales volume of new energy vehicles and shipments of lithium iron phosphate batteries continue to increase. Additionally, there is a growing need for efficient material handling in production lines.

One of the emerging requirements is for higher levels of cleanliness, even for common lifting equipment. To meet this need, we have introduced a new crane that can maintain cleanliness on workshop production lines. In this article, we will delve into the features and applications of the cleanroom overhead crane in the lithium battery industry, showcasing its pivotal role in enhancing precision and efficiency.

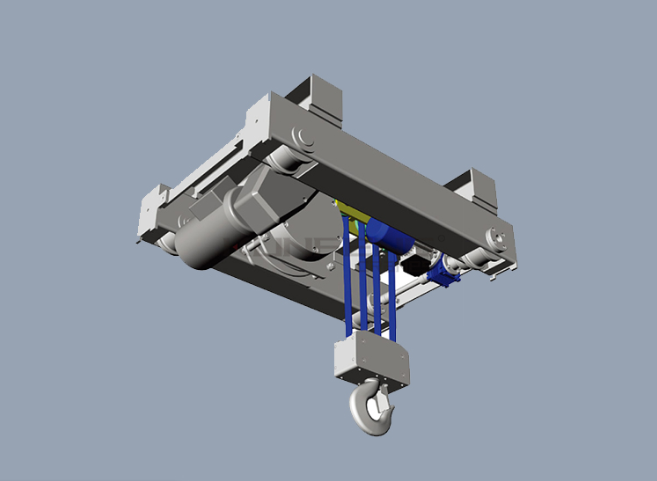

What is a Clean room Crane?

A cleanroom overhead crane is a specialized lifting device designed for use in cleanroom environments where stringent cleanliness and contamination control measures are crucial. It is constructed using stainless steel or other non-shedding materials to prevent the generation of particles during operation. The crane's smooth surfaces and enclosed design minimize the risk of contamination, making it ideal for cleanroom applications. For example, electric chain hoist in cleanrooms, special belt hoist for cleanroom lifting.

Applications in the Lithium Battery Industry:

1. Material Handling:

The cleanroom overhead crane plays a vital role in the movement of various materials and components within the lithium battery production process. It facilitates the safe and precise lifting, positioning, and transportation of raw materials, such as lithium-ion battery precursors, electrolytes, and other sensitive components. The crane's controlled and contamination-free operation helps safeguard the integrity of the materials and ensures high-quality battery production.

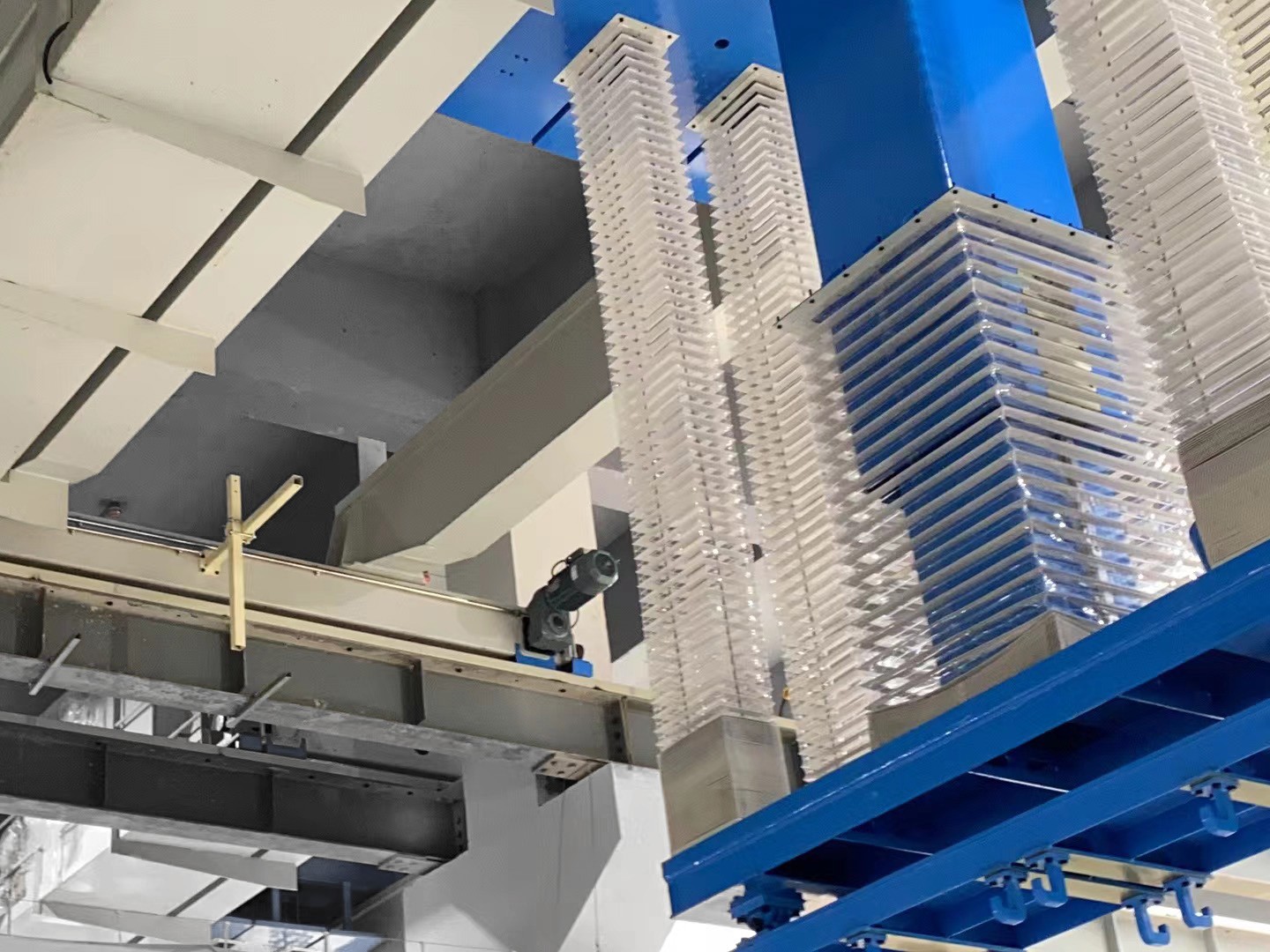

2. Electrode Manufacturing:

In the electrode manufacturing process, the cleanroom overhead crane aids in the precise handling and assembly of anode and cathode materials. It enables the lifting and positioning of delicate electrode sheets and foils, ensuring accurate alignment and reducing the risk of damage or contamination. The crane's smooth and controlled movements contribute to improved production efficiency and enhanced electrode quality.

3. Battery Assembly:

During the battery assembly process, the cleanroom overhead crane assists in the safe and accurate placement of battery cells into modules or packs. It offers controlled lifting and positioning capabilities, minimizing the risk of misalignment or mishandling. The crane's gentle and precise movements help maintain the integrity of the cells, ensuring consistent and reliable battery performance.

Benefits of Cleanroom Overhead Crane:

1. Cleanroom Compliance:

The cleanroom bridge crane is specifically designed to meet the stringent cleanliness requirements of dust free environments. Its smooth surfaces, enclosed design, and non-shedding materials minimize particle generation, ensuring compliance with clean room standards, as ISO 14644.

2. Precision and Control:

The bridge crane's advanced control mechanisms, such as variable speed and precise positioning, enable operators to perform lifting operations with exceptional accuracy. This precision enhances manufacturing quality, reduces errors, and optimizes production efficiency.

3. Contamination Prevention:

By minimizing the risk of contamination, the cleanroom bridge crane helps maintain the integrity and purity of lithium battery components. It contributes to the overall cleanliness of the production environment, reducing the likelihood of defects and ensuring consistent product quality.

Conclusion:

The cleanroom overhead crane has revolutionized material handling and assembly processes within the lithium battery industry. With its cleanroom compliant design, precise control, and contamination prevention capabilities, it enhances precision, efficiency, and product quality. By integrating the cleanroom overhead crane into lithium battery manufacturing facilities, companies can elevate their operations to meet the demanding cleanliness standards of the industry, ensuring the production of high-performance and reliable lithium batteries.

Interested in overhead crane? Then request now for an offer!