| European Crane Wheel Block for End Carriage

| Want to know more about European Crane Wheel Block for End Carriage?

Crane end carriage wheel block is wear-resistant, low-noise, and runs smoothly. It is suitable for bridge cranes and supports non-standard customization and processing according to drawings.

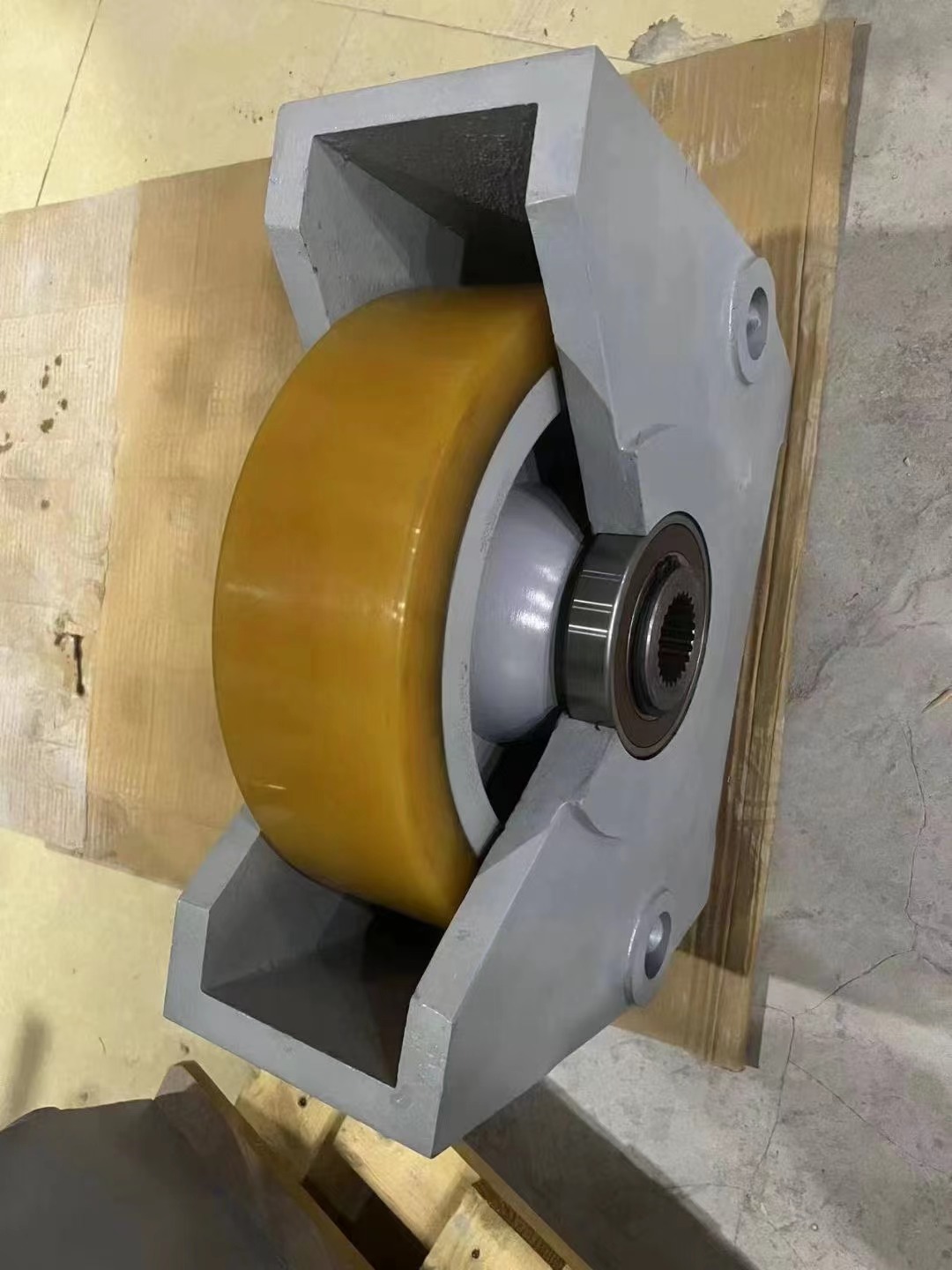

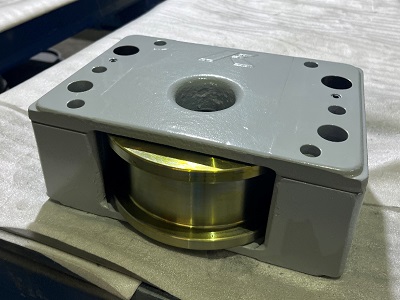

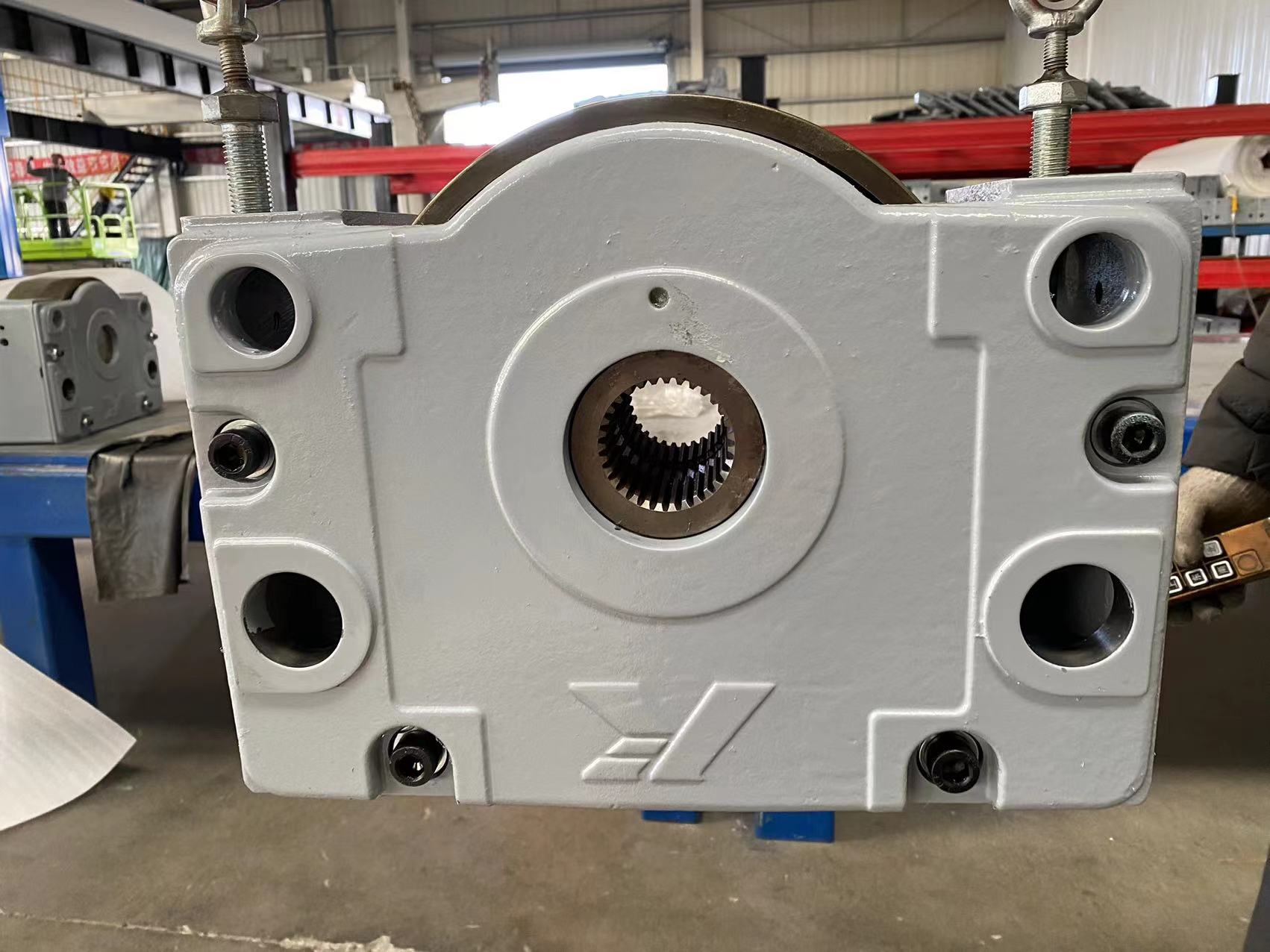

European crane wheel block for end carriage is a wheel installed on the end beam of the crane to support and guide the crane to walk on the track. A crane wheel block usually consists of a hub, a rim and a tire. The hub is the main part of the crane wheel block. The rim is used to prevent the running wheel from derailing, and the tires play a role in reducing friction and wear.

Crane end carriage wheel block comes in various sizes and types, and is mainly selected based on factors such as the tonnage of the crane, track type, and usage environment. Generally speaking, the larger the diameter of the crane wheel block, the stronger the load-bearing capacity, but it will also increase the operating resistance of the crane. Common crane wheel block size types include parameters such as diameter, width, and thickness. The specific size should be selected according to actual needs and specifications.

Design Features of Crane Wheel Block

● The rim is an important part to prevent the running wheel from derailing. Its height and width should be reasonably designed according to the type and size of the track to ensure the stability and safety of the running wheel on the track.

● The wheel hub is the main part of the crane wheel block. It is usually made of high-strength, high-wear-resistant alloy steel material to withstand the weight of the crane and the impact force during operation.

● The material of the tire has an important impact on the friction and wear properties of the crane wheel block. It is generally made of wear-resistant materials such as rubber or polyurethane to improve the life and performance of the crane wheel block.

The Function of Crane End Carriage Wheel Block

● The crane wheel block carries the entire weight of the crane and transfers the weight of the crane to the track through contact with the track to ensure the stable operation of the crane.

● The design of the Crane wheel block enables the crane to move linearly or in a curve along the track to meet various operating needs.

● Crane wheel block generates friction and impact with the track during operation. Through reasonable design and material selection, the impact of these friction and impact on the crane can be reduced and the service life of the crane can be extended.

We are a professional manufacturer of wheel block systems in China. We support customization according to working conditions. Please contact us for a detailed product catalog and reasonable quotation.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151